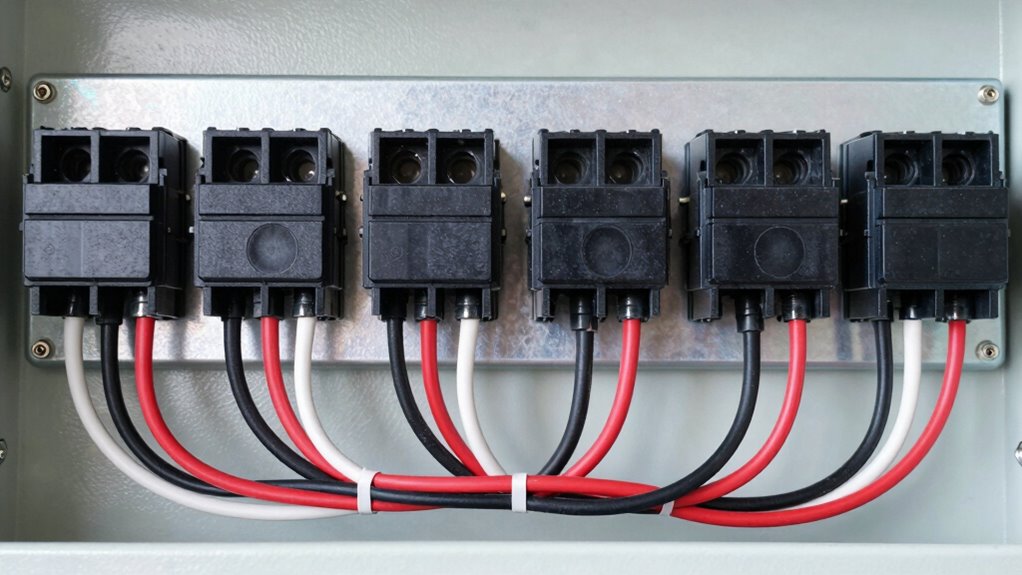

To split power cleanly and safely, use a distribution block to organize your wiring instead of spaghetti chaos. Connect your main power source to the distribution block, then run individual wires from it to each device or circuit. This keeps your setup neat, reduces risks of overloads, and makes future modifications easier. Choosing the right wire gauge for your total current load is essential. Keep exploring to discover how proper installation guarantees a reliable, tidy system.

Key Takeaways

- Use high-quality distribution blocks designed for your system’s current load to ensure safety and reliability.

- Select the correct wire gauge based on current draw and wire length to prevent overheating and voltage drops.

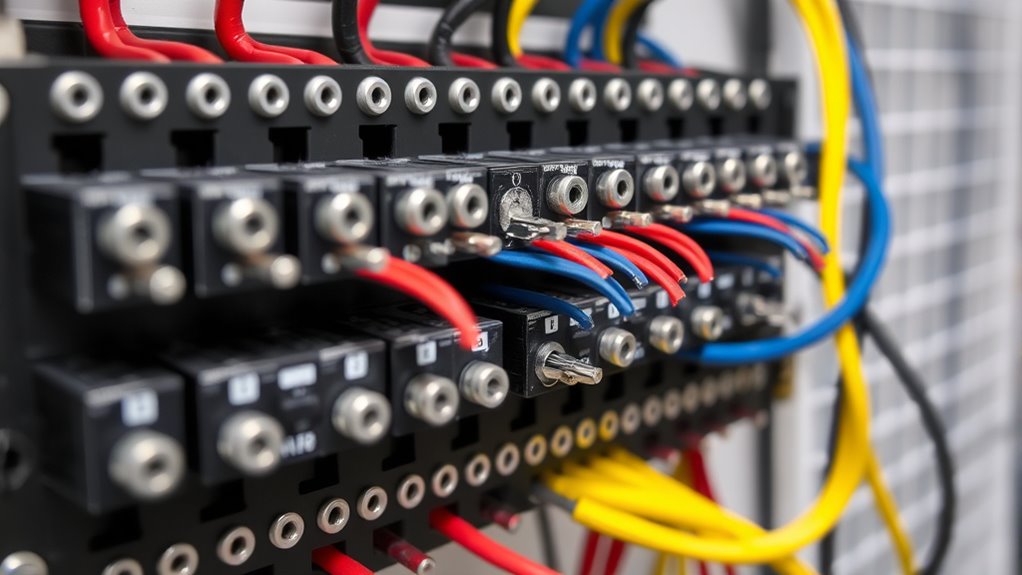

- Organize wiring neatly using proper cable management tools to avoid tangled, messy setups.

- Secure the distribution block firmly to prevent movement or damage during operation.

- Follow manufacturer instructions for installation, including proper fuse or circuit breaker placement for safety.

Are you familiar with what distribution blocks are and how they work? If not, let me clarify. Distribution blocks serve as central hubs that help you split power from a single source to multiple devices or circuits efficiently and safely. They’re especially useful in automotive, audio, or electrical projects where managing multiple connections without creating a tangled mess of wires is essential. Using a distribution block ensures a clean, organized setup that reduces the risk of short circuits, overloads, or accidental disconnections. Proper installation of these blocks can significantly improve the overall safety and reliability of your system.

When installing a distribution block, one of the most critical aspects to consider is wire gauge selection. Choosing the right gauge is vital because it directly impacts the safety and performance of your electrical system. If you pick a wire gauge that’s too thin, it can overheat under load, risking damage to your components or even fire. Conversely, using a wire that’s thicker than necessary can be more costly and less flexible, making installation more difficult. To determine the correct wire gauge, you need to consider the total current draw of your system and the length of the wire run. Shorter runs can typically handle slightly thinner wire, but longer runs demand thicker wire to compensate for voltage drop. Always refer to wire gauge charts and manufacturer recommendations to ensure you’re selecting appropriately. Additionally, understanding conductor capacity can help you choose the optimal wire size for your setup.

Frequently Asked Questions

Can Distribution Blocks Handle High-Current Loads Safely?

Yes, distribution blocks can handle high-current loads safely if you choose ones with appropriate current ratings and follow safety standards. Always check the maximum current capacity before installation to ensure it matches your power needs. Properly rated distribution blocks prevent overheating and electrical failures, keeping your wiring safe. By selecting the right block and adhering to safety guidelines, you can split power efficiently without risking damage or hazards.

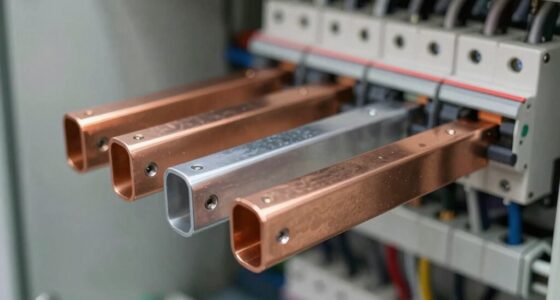

What Materials Are Best for Durable Distribution Blocks?

You should choose distribution blocks made from high-quality materials like copper or brass, as they offer excellent durability and conductivity. Look for options with corrosion-resistant coatings or finishes, such as nickel plating, to prevent corrosion over time. These materials guarantee your distribution block remains reliable, safe, and long-lasting, even in harsh environments. Prioritizing durability and corrosion prevention helps keep your wiring setup clean, efficient, and maintenance-free.

Are There Specific Sizes for Different Wire Gauges?

Think of distribution blocks as tailored suits—each size fits specific wire gauges perfectly. You need to match your wire gauge compatibility with the right distribution block sizes, ensuring a snug, secure fit. Smaller gauge wires require smaller blocks, while larger gauge wires need more substantial sizes. Choosing the correct size keeps your wiring neat and safe, avoiding a tangled mess, and gives your setup a professional, clean finish.

How Do I Prevent Corrosion in Distribution Blocks?

To prevent corrosion in distribution blocks, you should regularly inspect and clean them with a wire brush or contact cleaner. Apply dielectric grease to the connections to block moisture and oxidation. Keep the area dry and guarantee proper ventilation. Follow maintenance tips like tightening connections securely and avoiding exposure to harsh environments. These steps help maintain peak conductivity and extend the lifespan of your distribution blocks.

Can Distribution Blocks Be Used in Automotive and Home Applications?

Think of distribution blocks as versatile bridges connecting different worlds. Yes, you can use them in automotive and home applications, but also in marine setups and industrial environments. They serve as reliable power hubs, simplifying wiring and ensuring safe connections. Just make sure to choose blocks rated for your specific voltage and current needs. Proper selection and installation let you harness their full potential, whether in a car, house, boat, or factory.

Conclusion

Now you know how to split power safely, neatly, and efficiently. You understand the importance of choosing the right distribution block, organizing your wiring, and avoiding spaghetti mess. You can now plan your setup with confidence, guarantee safety with proper connections, and enjoy a clean, professional look. With these tips, you’re ready to tackle any wiring project—organized, streamlined, and hassle-free. Power up with precision, and keep your wiring neat and safe.