Before every pull, you should thoroughly inspect your soft shackle for signs of damage or wear. Check the manufacturer’s markings and load capacity to make certain they’re legible and correct. Examine the shackle for cracks, corrosion, nicks, or deformation, and verify that pins are fully engaged. Look for heat damage, weld splatter, and exposed core material not exceeding 100mm. If you find any issues, remove and tag the shackle; proper inspection details await if you keep going.

Key Takeaways

- Visually verify manufacturer’s markings, load capacity, and check for any visible damage like cracks, corrosion, or deformation.

- Inspect for signs of wear, cuts, burns, pitting, or gouges that may compromise the shackle’s integrity.

- For soft shackles, check for heat damage, discoloration, weld splatter, arc strikes, and core exposure exceeding 100mm.

- Ensure pins are fully engaged, threaded smoothly, and that the shackle has no elongation or distortion indicating overload.

- Remove damaged shackles from service, tag as “Out of Service,” and store separately to prevent accidental reuse.

Verify Manufacturer’s Markings and Load Capacity

To verify your soft shackles are safe to use, you must verify that the manufacturer’s markings and load capacity are clearly visible and legible. Examine the shackles closely for the manufacturer’s name, trademark, and rated load identification. These markings confirm the shackle’s compliance with safety standards like ASME B30.26. If the markings are faded, smudged, or missing, it’s unsafe to use the shackles, as you can’t confirm their rated capacity. Always ensure these details are readable before each use. Proper markings help prevent overload accidents and ensure the shackles meet safety requirements. If you notice any illegibility, don’t attempt to use or repair the shackle; replace it to maintain safety during your operation. Regular inspection procedures are essential to ensure ongoing safety and compliance. Additionally, vetted shackles that undergo routine checks help identify potential issues like wear or damage early, preventing accidents during critical pulls. Consistent inspections and adherence to safety standards are key to safe operation. Conducting these inspections regularly helps maintain the integrity of the shackles and reduces the risk of failure during demanding pulls, especially when considering factors like wear and corrosion.

Examine for Visible Damage or Wear

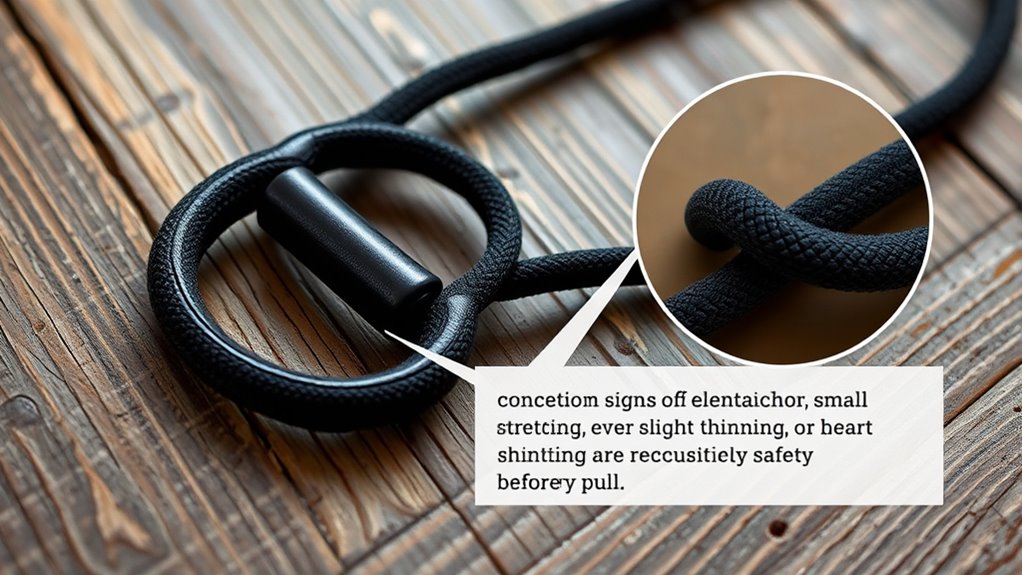

Carefully inspect the soft shackle for any signs of visible damage or wear that could compromise its safety. Look closely at the entire length for cuts, burns, or abrasions that may weaken the material. Check for excessive pitting, corrosion, nicks, or gouges that could cause failure. Examine the components for bent, twisted, or distorted parts, and verify there are no cracks or broken areas. Confirm that no exposed core material exceeds 100mm, as this indicates damage. Listen for unusual noises like cracking or snapping during inspection, which can signal internal issues. Also, assess for signs of fiber snapping or elongation, which suggest overstress. Regularly connected equipment can help monitor these components for early warning signs of wear. Incorporating advanced testing methods can further improve the accuracy of inspections without damaging the shackle. Utilizing remote sensing technology can provide real-time data on the integrity of the shackle during use. If you notice any damage or wear, remove the shackle from service immediately.

Check for Elongation or Deformation of Components

Elongation or deformation of components can substantially weaken a soft shackle’s integrity, so it’s essential to scrutinize for any signs of these issues during inspection. Look closely at the load-bearing parts, especially the eyes and body, for any stretching or shape changes. Deformed areas may appear elongated, flattened, or distorted, indicating overstress. Use the table below to help identify potential problems:

| Sign of Elongation | Potential Cause |

|---|---|

| Excessive stretching | Overloading or prolonged use |

| Irregular shape | Impact damage or fatigue |

| Reduced diameter | Wear or material degradation |

| Bent or twisted | Sudden shock or improper handling |

Additionally, inspecting for material fatigue can help identify early signs of failure before they become critical. Always replace shackles showing signs of elongation or deformation before use. Incorporating sustainable and secure inspection practices ensures the longevity and safety of your equipment.

Inspect the Integrity of Pins and Body Parts

Inspecting the integrity of pins and body parts is essential to guarantee your soft shackle remains safe and reliable. You need to carefully examine all components for signs of damage or wear. Look for cracks, bends, or distortions that could compromise strength. Check for elongation or deformation in the pin threads and ensure they are fully engaged. Inspect the body for cracks, gouges, or any signs of fatigue. Confirm that there are no exposed core materials exceeding 100mm, which indicates excessive damage. Verify that there are no corrosion, pitting, or nicks that could weaken the structure. Verify that pins are properly seated and threaded smoothly without excessive thread damage. If you notice any damage or irregularities, remove the shackle from service immediately. Regular inspection practices are crucial to maintaining safety and preventing failure during use. Additionally, regularly testing the load capacity of the shackle can help identify hidden weaknesses before a critical failure occurs. Incorporating visual and functional checks into your routine can further enhance overall safety and reliability, especially considering the importance of proper material integrity in ensuring longevity. Regularly consulting manufacturer guidelines can also provide specific inspection tips tailored to your equipment.

Assess for Excessive Pitting, Corrosion, or Nicks

Evaluating for excessive pitting, corrosion, or nicks is essential to maintaining your soft shackle’s strength and safety. These issues weaken the material, risking failure during use. Carefully inspect the entire surface for deep pits, rust, or corrosion spots that compromise integrity. Nicks or gouges can create stress risers, increasing the chance of breakage. Use a bright light and magnification if needed to spot subtle damage. Be especially cautious around contact points and load-bearing areas. Recognizing and addressing material fatigue early can prevent unexpected failures. Regular inspections help identify early signs of material degradation, ensuring your soft shackle remains safe and reliable over time. Additionally, understanding how electric bikes and their components perform can inform your maintenance routines and safety checks. Being aware of corrosion resistance in materials can guide you in choosing more durable options for your safety gear. Paying attention to performance factors can help extend the lifespan of your equipment and ensure safety during critical moments.

Ensure Proper Engagement and Thread Condition

Proper engagement of the shackle pin and ensuring the threads are in good condition are essential for safe operation. You should always verify that the pin is fully threaded into the shackle body without cross-threading or cross-loading. Check that the threads are clean, free of dirt, debris, or corrosion, which can compromise holding strength. Inspect for any signs of thread damage, such as nicks, flattening, or signs of wear that could cause the pin to loosen under load. Make sure the pin seats properly and threads smoothly without resistance. If threads are damaged or the pin doesn’t engage fully, replace the shackle or pin immediately. Proper engagement prevents accidental loosening or failure, ensuring your soft shackle remains secure during every pull. Regularly inspecting thread integrity can help identify issues early and maintain safety. Paying attention to corrosion prevention techniques can extend the lifespan of your shackles and ensure ongoing safety.

Look for Signs of Heat Damage or Weld Splatter

Heat damage or weld splatter can compromise the integrity of your soft shackle, so it’s essential to identify these issues during your inspection. Look closely at the entire surface for discoloration, blisters, or burn marks, which indicate heat exposure. Weld splatter appears as small, shiny metal spots or rough patches that don’t belong. These signs suggest localized weakening or potential failure points. Use the following table to guide your assessment:

| Damage Type | What to Look For |

|---|---|

| Heat Damage | Discoloration, blistering, burn marks |

| Weld Splatter | Shiny metal spots, rough patches |

| Arc Strikes | Small craters, uneven surface |

Address any signs of damage immediately by removing the shackle from service.

Confirm No Exposed Core Material Exceeds Limits

To guarantee the safety and integrity of your soft shackle, you must verify that no exposed core material exceeds 100mm. Carefully inspect the entire length of the shackle, paying close attention to areas where the cover may be worn or damaged. Exposed core material can weaken the shackle’s strength and increase the risk of failure. If you find any section where the core is visible beyond the 100mm limit, remove the shackle from service immediately. Do not attempt to repair or reinforce it yourself; instead, tag it out and have it professionally evaluated or replaced. Maintaining this limit ensures your soft shackle remains safe and reliable during operation, preventing potential accidents caused by compromised integrity.

Remove and Tag if Damage or Unsafe Conditions Are Found

When you identify damage or unsafe conditions on a soft shackle, it’s essential to remove it from service immediately. Do not attempt to repair or reuse the shackle until a qualified professional inspects and approves it. Tag it clearly with an “Out of Service” label to prevent accidental use. Check for signs like deformation, cracks, or exposed core material exceeding 100mm. If you notice any wear, cuts, or corrosion, take the shackle right away. Store it separately to prevent future use until proper repairs are made. Always follow your organization’s safety protocols for tagging and documentation. Removing and tagging damaged shackles helps ensure safety, preventing potential failures that could cause injuries or equipment damage during pulls.

Frequently Asked Questions

How Often Should I Perform a Soft Shackle Safety Inspection?

You should perform a safety inspection of your soft shackle every day or before each use. Check for signs of wear, elongation, cuts, or damage to the cover. Look for corrosion, deformation, or any indication of compromised integrity. If you notice any issues, remove it from service immediately. Regular inspections help make sure your soft shackle remains safe and reliable, preventing potential failures during use.

What Are the Specific Removal Criteria for Damaged Soft Shackles?

You should remove a soft shackle if you notice any damage that compromises its integrity. This includes visible cracks, distortions, elongation, or if the exposed core exceeds 100mm. Also, remove it if there’s evidence of unauthorized welding, excessive wear, or missing/illegible markings. If the shackle shows signs of heat damage, corrosion, or any other hazard, it’s safest to take it out of service immediately and replace it.

Can I Repair a Soft Shackle With Minor Wear or Damage?

You shouldn’t repair a soft shackle with minor wear or damage. If you notice elongation, cracks, or exposed core exceeding 100mm, remove it from service immediately. Attempting repairs can compromise its strength and safety. Instead, replace the shackle with a new one that meets ASME B30.26 standards. Regular inspections are key to identifying issues early, so always follow the manufacturer’s guidelines and safety criteria.

What Is the Proper Way to Tag Out a Damaged Soft Shackle?

You should tag out a damaged soft shackle by clearly marking it as out of service with a durable tag that states “Do Not Use” or “Out of Service.” Attach the tag securely near the damage area, making sure it’s visible. Remove the shackle from the load, and store it separately to prevent accidental use. Always follow your workplace’s specific tagging procedures and ensure a qualified person approves its removal.

How Do Environmental Conditions Affect Soft Shackle Inspections?

Think of environmental conditions as the weather affecting your soft shackle’s health. Rain, salt, or mud can hide damage or cause corrosion, making inspections tricky. You need to look closely for rust, pitting, or wear that might be masked by dirt or moisture. After exposure, make certain you dry, clean, and thoroughly inspect the shackle. If in doubt, replace it to keep your gear safe and reliable during every pull.

Conclusion

Always take a moment to inspect your soft shackle before each use—it’s quick, easy, and can prevent costly accidents. Some might think it’s unnecessary or time-consuming, but skipping this step risks failure when you need it most. By staying vigilant, you not only protect yourself and others but also extend the life of your equipment. A little extra effort goes a long way in keeping your pulls safe and reliable every time.