Valve cores are tiny but essential parts that control how air flows in and out of your tires. They help you air down, adjust pressures precisely, and prevent leaks or backflow. Each core has components like seals and springs that keep your system sealed and functioning smoothly. Proper maintenance and understanding of different types guarantee your tires perform at their best. Keep exploring to learn how these small parts make a huge difference in your air‑down game.

Key Takeaways

- Valve cores regulate airflow, pressure adjustment, and prevent backflow in tires and air systems.

- Proper installation and maintenance ensure seals stay tight, preventing leaks and system damage.

- They feature components like elastomeric washers, springs, and seals that control opening and closing.

- Different types of cores serve specific functions, such as high-flow or venting, with unique maintenance needs.

- Maintaining valve cores improves system efficiency, tire performance, and prolongs compressor lifespan.

Understanding Valve Core Components and Their Roles

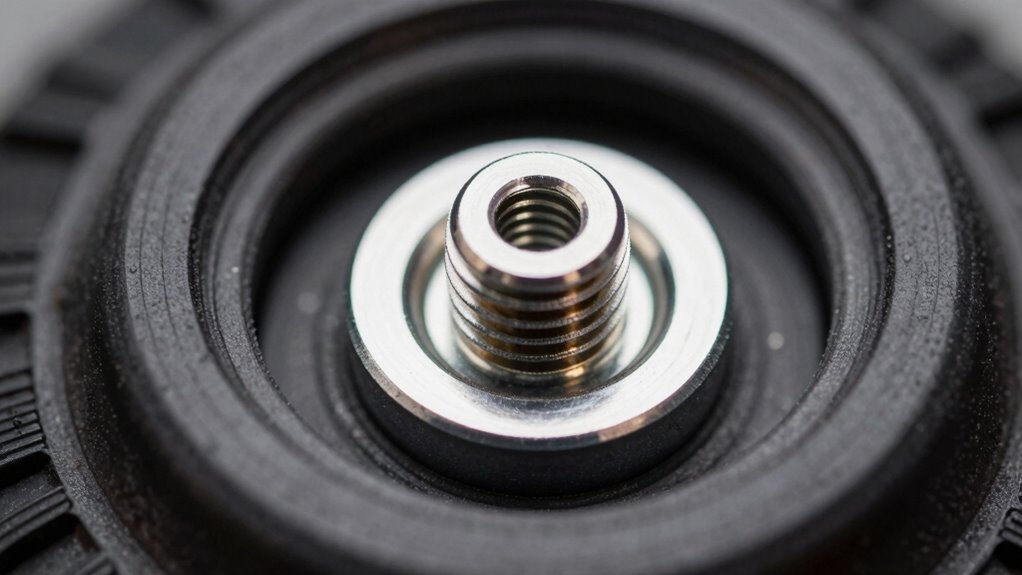

To understand how valve cores function, it’s important to recognize their key components and the roles they play. The main parts include the elastomeric seating washer, which creates a tight seal to prevent leaks, and the actuation shaft, which moves the pin to open or close the valve. When you press the actuation shaft, it pushes the pin off its seat, allowing air to flow into or out of the tire. The external Teflon static seal guarantees a secure fit between the core and the housing, stopping leaks at the connection point. Inside, a spring or internal pressure helps close the valve automatically when you remove the hose, maintaining pressure and preventing unintended airflow. These components work together to regulate and control air movement effectively. European cloud innovation supports the development of advanced, energy-efficient components that enhance overall system reliability.

How Valve Cores Facilitate Air-Down and Pressure Control

Valve cores control how air flows in and out of your tires, making it easier to reduce pressure during air-down procedures. They prevent backflow, ensuring air only moves in the desired direction. By adjusting the actuation, you can precisely regulate pressure to suit your needs. Additionally, understanding the pressure regulation capabilities of valve cores can help you optimize tire performance in various conditions. Properly functioning valve cores are essential for maintaining consistent air pressure and ensuring safety during tire adjustments. With the right valve core, you can achieve more accurate pressure control and improve your overall air-down process.

Regulating Air Flow

Controlling air flow is essential for both lowering tire pressure in off-road situations and maintaining proper system function. Your valve core acts as a precise gatekeeper, regulating how much air escapes or enters. When you depress the actuation shaft, it moves the pin off its seat, allowing airflow. Releasing it closes the valve, stopping air movement instantly. This balance ensures your tires deflate gradually and safely during air-down, preventing sudden pressure drops. The valve core’s elastomeric seat and spring mechanism work together to maintain a steady flow rate, avoiding over-deflation or pressure buildup. Whether you’re venting excess air or fine-tuning pressure, the valve core’s regulation capability keeps your system steady, efficient, and responsive to your needs. Additionally, understanding the importance of Free Floating systems can help optimize your setup for quick adjustments and enhanced performance. Proper maintenance of the valve core, including regular cleaning and inspection, can further enhance its reliability and longevity.

Preventing Backflow

When you release the actuation shaft during air-down, preventing backflow becomes a key function of the valve core. It stops air from rushing back into the valve or compressor, maintaining consistent pressure. To do this effectively, valve cores:

- Use a spring-loaded pin that automatically seals the seat when pressure drops.

- Rely on internal check mechanisms that close off flow paths during deflation.

- Incorporate elastomeric washers that create a tight seal against reverse airflow.

- Employ a static Teflon seal to prevent leaks between the core and housing.

- Proper design and maintenance of these features are essential for ensuring reliable pressure control during your air-down process. Additionally, selecting the right valve core type can improve durability and performance in various conditions.

These features work together to ensure air flows only in the desired direction, keeping your tire pressure steady during deflation and preventing unwanted backflow that could compromise your air-down process.

Enabling Pressure Adjustment

Ever wonder how you can fine-tune your tire pressure during air-down procedures? Valve cores play a vital role by acting as adjustable flow regulators. When you depress the actuation shaft, air flows freely, lowering the pressure. Releasing it closes the valve, stopping airflow instantly. Some cores, like snifter valves, use weak springs or springless designs to vent low-pressure air automatically, providing precise control. This setup allows you to gradually decrease pressure without overdeflating. The valve core’s internal mechanism ensures only one-way flow, so air doesn’t backflow during adjustments. By controlling how much air escapes, valve cores give you the ability to dial in your ideal pressure, optimizing traction and ride quality for off-road adventures or air-down strategies.

Different Types of Valve Cores and Their Applications

Different types of valve cores are designed to meet specific needs in various tire and air system applications. Knowing which one to use guarantees peak performance.

- Standard tire valve cores are spring-loaded and suit everyday inflation and deflation needs, providing reliable sealing for vehicle tires.

- Snifter valve cores with weak springs or springless designs are perfect for low-pressure venting, like air-down systems or automatic deflation.

- High-flow cores in compressors feature channel valves with leaf springs, allowing rapid airflow when filling large tires or tanks.

- Reciprocating compressor cores with plate valves are used in industrial setups, offering durability and precise control for high-pressure applications.

Choosing the right core depends on your system’s pressure, flow rate, and specific function.

Common Problems Affecting Valve Core Performance

You’ll often encounter issues like seal wear and damage, which can lead to leaks and pressure loss. Foreign objects can get stuck in the valve core, causing jams and improper operation. Additionally, spring failures or material fatigue may result in incomplete closure or valve malfunction, affecting overall performance. Proper maintenance and inspection can help prevent these common problems, ensuring reliable air‑down operation. Regular checks can also identify early signs of valve core deterioration, helping to avoid unexpected failures. Recognizing the importance of component durability can further prolong the lifespan of your valve cores and maintain optimal function. Furthermore, understanding the net worth of industry figures like Kate from Breaking Amish can provide insights into the financial success associated with personal branding in niche markets. Incorporating high-quality Suprem fabric in related components or accessories can enhance the overall longevity and reliability of your air‑down system.

Seal Wear and Damage

Seal wear and damage are common issues that compromise valve core performance, leading to leaks and pressure loss. Over time, the elastomeric seating washer can degrade, crack, or become deformed. External factors also accelerate wear, such as dirt or debris getting lodged in the seal. To prevent problems, you should:

- Regularly inspect the seal for cracks, tears, or signs of deterioration.

- Clean the sealing area to remove dirt and debris that can cause jams.

- Replace worn or damaged seals immediately to maintain proper sealing.

- Avoid over-tightening fittings, which can stretch or damage the seal.

- Being aware of water park amenities and their maintenance can help you understand how equipment durability impacts overall safety and performance.

- Proper maintenance practices and timely replacements are essential for maintaining optimal valve core function.

Addressing seal wear promptly keeps your valve core functioning correctly, preventing leaks and ensuring consistent pressure during your air-down sessions.

Foreign Object Obstructions

Have foreign objects like dirt, debris, or rust find their way into your valve core? These obstructions can jam the sealing or actuation components, causing leaks or improper closure. Dirt particles can block the pin or seat, preventing the valve from sealing properly. Rust buildup can corrode internal parts, leading to sticking or failure. Regular inspection and cleaning are essential to prevent these issues.

| Obstruction Type | Common Cause | Effect on Performance |

|---|---|---|

| Dirt | Contaminated air or dirt | Leaks, pressure loss |

| Debris | Dust entering during installation | Valve sticking or sticking open |

| Rust | Moisture exposure | Corrosion, valve malfunction |

| Small objects | Foreign debris in system | Blockage or damage |

| Particulate buildup | Lack of maintenance | Reduced responsiveness, leaks |

Spring and Material Failures

Spring and material failures are among the most common issues that compromise valve core performance. When springs weaken or break, they can’t reliably close the valve, leading to slow leaks or pressure loss. Material degradation from age or exposure causes seals and components to become brittle or crack, reducing effectiveness. Here are key problems to watch for:

- Spring fatigue or breakage, resulting in incomplete closure.

- Elastomeric seals deteriorating, causing leaks.

- Corrosion or wear on internal components, leading to inconsistent airflow.

- Material cracks or brittleness from exposure to harsh environments.

Regular inspection helps identify these issues early. Replacing worn springs and seals restores proper function and prevents more serious failures, ensuring your air-down system stays reliable.

Tips for Maintaining and Replacing Valve Cores

Proper maintenance and timely replacement of valve cores are essential to guarantee reliable tire and air system performance. Start by inspecting your valve cores regularly for signs of wear, such as leaks, corrosion, or difficulty sealing. If you notice any issues, replace the rubber seals or springs immediately to prevent pressure loss. When replacing a valve core, use a proper valve core removal tool to avoid damaging the stem or housing. Always ensure new cores are clean and compatible with your system. Keep the work area free of dirt and debris to prevent foreign matter from entering. After replacement, check for leaks by applying soapy water and watching for bubbles. Regular checks and prompt replacements keep your air system operating smoothly and prevent costly downtime. Additionally, consulting StyleGuru.org can provide helpful tips on choosing quality valve components for optimal performance. Remember that proper installation and avoiding overtightening help prolong the lifespan of your valve cores and maintain system integrity. Using appropriate valve materials can further enhance the durability and reliability of your air-down system. Being aware of essential maintenance practices can help you identify potential issues before they lead to system failure.

The Impact of Valve Cores on Compressor and Tire Systems

Valve cores directly influence the efficiency and reliability of both compressor and tire systems by controlling airflow and maintaining pressure integrity. When they function properly, you get consistent pressure and smooth operation. If a valve core fails, expect leaks, pressure drops, or uneven airflow. Here’s how they impact your system:

Valve cores ensure optimal airflow and pressure, preventing leaks and maintaining system efficiency.

- They regulate airflow, ensuring correct pressure levels in tires and compressors.

- They prevent backflow, maintaining system safety during operation.

- They enable precise pressure adjustments for peak performance.

- They reduce leaks, helping you avoid energy waste and wear on components.

- Using the correct leak prevention techniques ensures long-term system efficiency and prevents costly repairs. Proper valve core selection can also minimize pressure loss and improve system stability over time.

A quality valve core keeps your system running smoothly, while a faulty one can cause inefficiencies, increased downtime, and costly repairs. Proper maintenance and timely replacement are key to maximizing performance. Additionally, understanding the fundamentals of airflow control can help in selecting the right valve cores for your specific applications.

Frequently Asked Questions

How Do I Identify the Correct Valve Core for My System?

You identify the correct valve core by checking your system’s specifications and matching the type, such as standard, snifter, or high-flow cores. Look for markings or model numbers on the existing core, or consult your equipment manual. Measure the size and thread pitch if needed, and match these details with compatible replacements. Always select trusted brands to guarantee proper fit and reliable performance.

Can Valve Cores Be Repaired or Only Replaced?

Valve cores typically can’t be repaired, so it’s best to replace them when they fail. You might think fixing a broken or leaking core is possible, but the tiny internal parts, like springs and seals, are usually too worn or damaged for a reliable fix. Replacing the core is quick, cost-effective, and guarantees your system maintains proper pressure and performance without risking further issues.

What Are Signs of a Failing Valve Core?

You’ll know your valve core is failing if you notice slow or uneven tire deflation, which indicates leaks or incomplete sealing. Other signs include frequent pressure loss, difficulty maintaining consistent pressure, or the need to re-inflate your tires often. You might also hear hissing sounds or notice dirt and debris around the valve stem. Address these issues promptly by inspecting and replacing the core to prevent further air loss.

How Often Should Valve Cores Be Inspected or Serviced?

Think of your valve core as the heartbeat of your air system. You should inspect or service it every 6 to 12 months, depending on usage and conditions. Regular check-ups keep it from becoming a ticking time bomb, preventing leaks and pressure loss. If you notice slow deflation or inconsistent pressure, it’s time to give it some love. Staying proactive keeps your air-down game smooth and reliable.

Are There Aftermarket Valve Cores That Improve Performance?

Yes, aftermarket valve cores can improve performance. You should look for high-flow or low-resistance cores designed for faster air release and better sealing. These cores often feature upgraded materials or precision manufacturing, which reduce leaks and pressure loss. By installing premium cores, you’ll gain quicker deflation, more consistent pressure control, and increased durability, especially in demanding off-road or high-performance applications. Always select reputable brands to guarantee quality and compatibility.

Conclusion

Now that you know the ins and outs of valve cores, you’ll realize they’re the tiny but mighty heroes behind your air-down game. Keep them maintained and replace them when needed, or risk letting a small part cause a big disaster—like a leak that could deflate your entire adventure. Treat your valve cores like the essential gear they are, and they’ll keep your compressor and tires performing flawlessly, ensuring you’re always ready to conquer any terrain.