Pure sine wave power provides smooth, stable electricity similar to utility grids, making it vital for sensitive electronics, motor loads, and precise equipment. When you need reliable, low-distortion power, a pure sine inverter is your best choice. However, for simple devices like LED lights or chargers, a modified sine wave might suffice. To guarantee you get what’s right, understanding key performance metrics and marketing claims is essential—if you want to explore more, there’s plenty to learn.

Key Takeaways

- Pure sine wave power provides smooth, stable AC output similar to utility grids, essential for sensitive electronics and precise measurements.

- It minimizes electrical noise and EMI, reducing interference and prolonging electronic component lifespan.

- Modified sine wave inverters are sufficient for simple devices like lights and chargers but may cause issues with motor loads or sensitive equipment.

- Marketing claims like “true sine” can be misleading; verify waveform quality via specifications such as THD (<3%) before purchase.

- For critical or sensitive applications, choosing a pure sine inverter ensures better performance, reliability, and longer device life.

Understanding the Basics of Pure Sine Wave Power

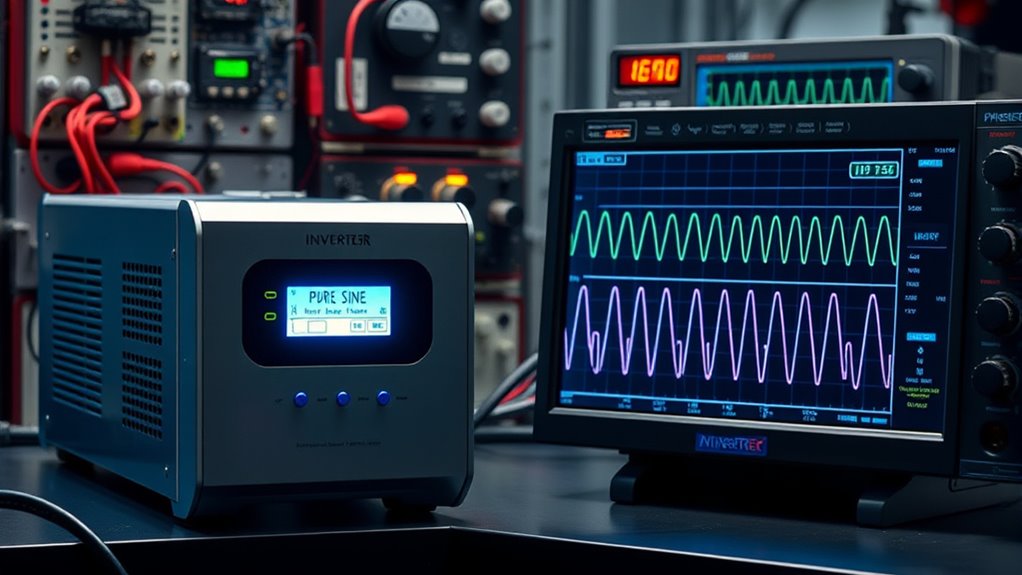

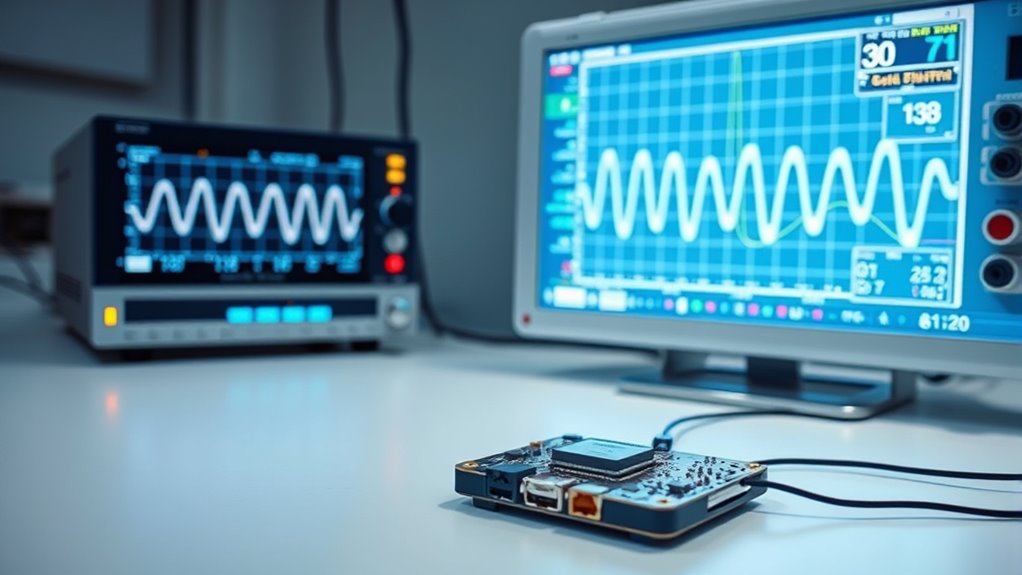

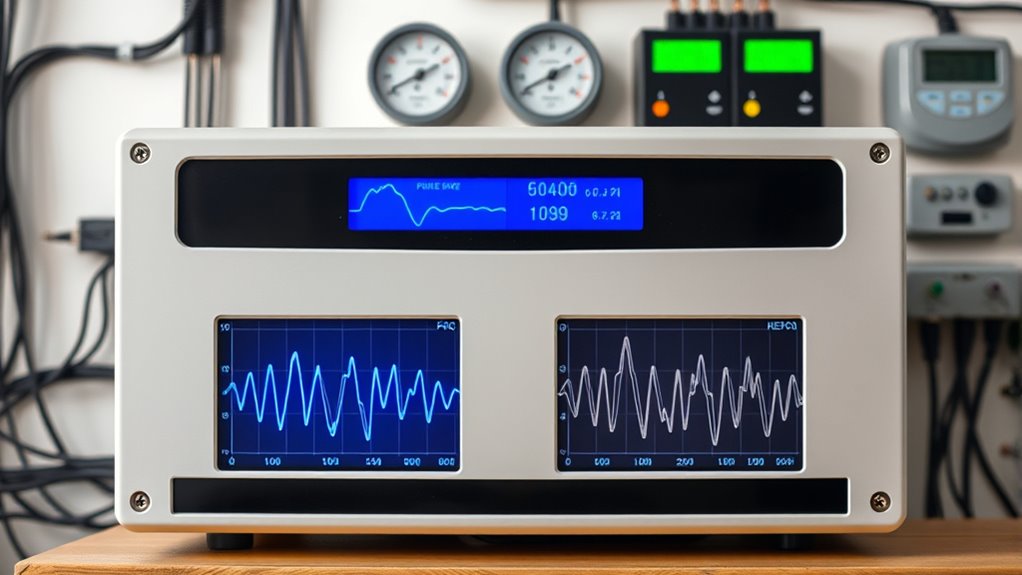

Pure sine wave power generates an electrical output that closely resembles the smooth, continuous waveform found in utility grids. It produces a sinusoidal voltage that varies smoothly over time, ensuring clean, stable power delivery. To create this waveform, the inverter first converts DC from a battery or solar panel into a high-frequency switched waveform. Then, it shapes this signal using pulse-width modulation (PWM) or filtering techniques into a pure sine form. Inside, key components like oscillators, power switches (MOSFETs or IGBTs), transformers, and control circuits work together to maintain accurate voltage and frequency. This process results in a reliable, low-distortion AC power source, ideal for sensitive electronics and equipment that demand high-quality power to operate correctly. European cloud innovation emphasizes the importance of reliable power solutions in supporting sustainable and secure cloud infrastructure. Additionally, advances in power modulation techniques have enhanced the efficiency and output quality of pure sine wave inverters. The use of advanced control methods further optimizes waveform accuracy and reduces harmonic distortion, ensuring even better performance.

Why Sensitive Equipment Needs Pure Sine Power

Sensitive equipment depends on precise timing and control to operate correctly, which pure sine power provides reliably. Electrical noise and harmonics from non-sine wave sources can cause malfunctions or degraded performance. Using pure sine power ensures your devices run smoothly and accurately without interference. Additionally, essential oils with calming or antimicrobial properties may support the overall health and longevity of sensitive electronic components by reducing environmental stressors. A clean power supply also minimizes electrical interference, further protecting sensitive devices from potential damage. Implementing power conditioning can further enhance the stability and lifespan of your electronic equipment.

Precise Timing and Control

When equipment relies on precise timing and control signals, the quality of the power supply becomes critical. Pure sine power offers a smooth, stable waveform that guarantees internal clocks and control circuits operate accurately. Any waveform irregularity can cause timing errors, leading to malfunctions or data corruption. Consider this table as a visual aid:

| Characteristic | Pure Sine Power | Modified Sine Power |

|---|---|---|

| Waveform Shape | Smooth sinusoid | Stepped, blocky steps |

| Voltage Stability | Very stable | Slight fluctuations |

| Timing Precision | Accurate, reliable | Potential delays or errors |

With pure sine power, your sensitive equipment receives consistent signals, preventing mis-timing and ensuring peak performance. Lower quality waveforms risk disruptions that compromise control accuracy. Ensuring power quality is essential for maintaining the integrity of advanced electronic systems, especially where synchronous timing is crucial for proper operation. A lack of waveform purity can result in subtle yet impactful performance issues over time. Additionally, electronic component longevity is often extended when powered by pure sine wave sources, reducing maintenance and replacement costs. Moreover, the compatibility of equipment with power sources can be significantly improved by using pure sine wave inverters or generators.

Reduced Electrical Noise

Electrical noise generated by non-sine wave inverters can interfere with the delicate components inside sensitive equipment, causing malfunctions or degraded performance. When your gear relies on precise signals, the waveform’s purity matters. Non-sine inverters produce a stepped or distorted output that introduces electrical interference. This noise can:

- Disrupt radio or audio signals, causing hum or static

- Trigger false readings in measurement or control devices

- Increase electromagnetic interference (EMI), affecting nearby electronics

- Cause overheating or wear in sensitive motors and transformers

- Impact on sensitive electronics can be significant when electrical noise levels are high. Ensuring your power source maintains a clean, stable waveform is essential for optimal performance.

Using pure sine power ensures a smooth, consistent waveform that minimizes these issues. It reduces electrical interference, helping your sensitive equipment operate reliably and with less noise-related distortion. For critical systems, clean power isn’t just a luxury—it’s a necessity, especially in environments where electrical noise can disrupt connected devices or compromise system integrity.

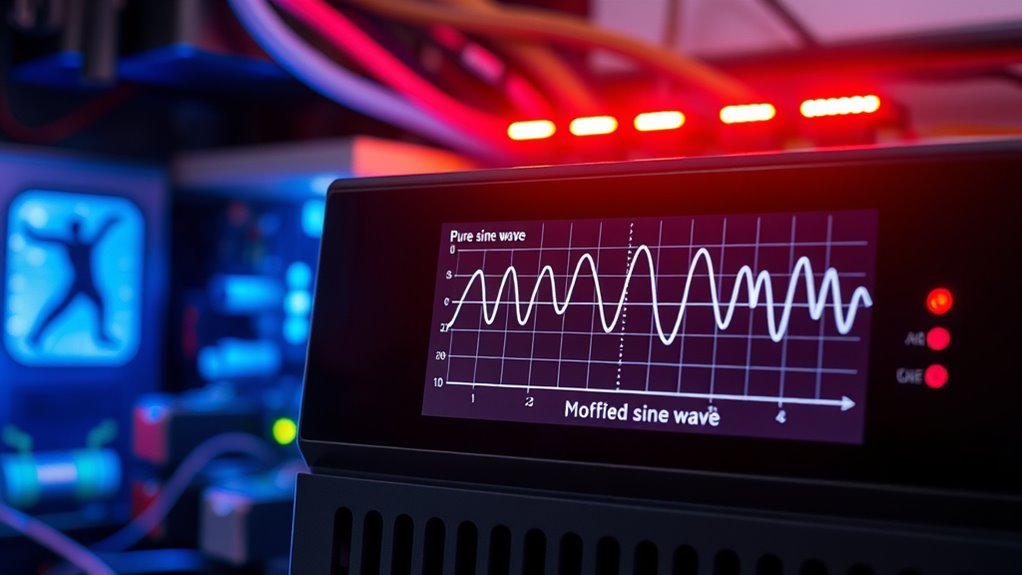

When Modified Sine Wave Might Be Sufficient

Modified sine wave inverters can be a practical choice when powering basic, non-sensitive devices that don’t require a perfectly clean power source. If you’re using simple appliances like incandescent lights, basic chargers, or small kitchen gadgets, the stepped waveform usually won’t cause issues. Many low-cost electronics, such as radios or LED lights, operate normally on modified sine. Short-term or emergency use often justifies choosing a cheaper, lighter inverter to save money. Low-power tools and small appliances with simple motors may produce some noise or heat, but still function adequately. For applications where cost, weight, and simplicity matter more than perfect power quality, a modified sine wave inverter can deliver reliable performance without the higher expense of pure sine options. Proper power quality and piercing care and hygiene can help prevent potential issues with sensitive electronics if you plan to use inverters in conjunction with other devices. Additionally, understanding the energy efficiency of your inverter can help optimize overall performance and reduce operational costs. Recognizing the limitations of modified sine wave inverters can guide you in making informed choices for your specific power needs. Considering the compatibility with electronic devices is essential to ensure your appliances operate safely and effectively.

Key Performance Metrics to Consider

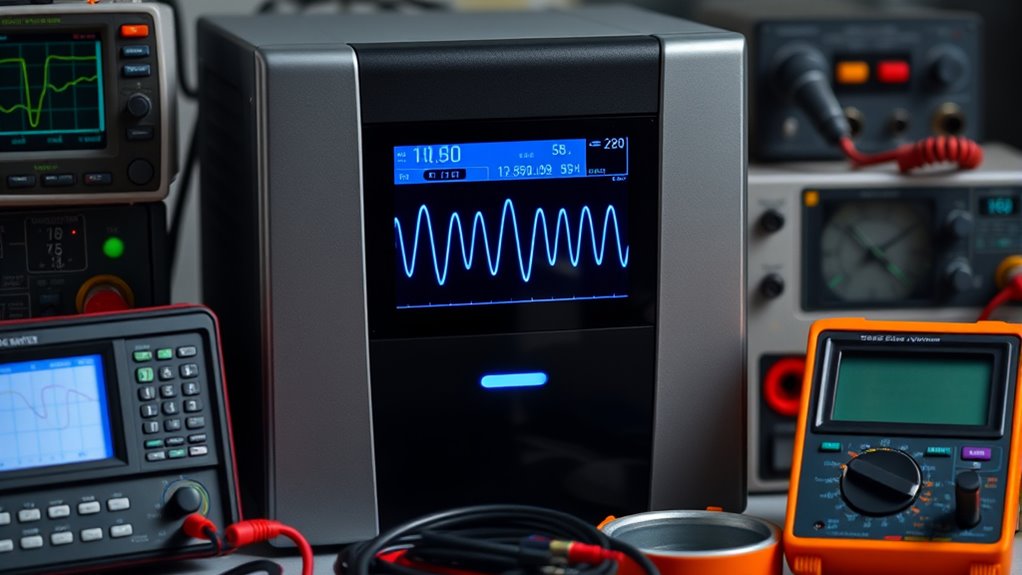

You need to pay close attention to voltage accuracy and stability to make certain your equipment runs smoothly without fluctuations. Voltage regulation is essential for maintaining consistent power output. Proper voltage regulation prevents equipment damage caused by voltage sags or surges. Harmonic distortion levels also matter because high THD can cause overheating, noise, and reduced lifespan for sensitive devices. Additionally, choosing a pure sine inverter with low THD levels ensures your devices operate as intended without electromagnetic interference. Regularly monitoring power quality can help detect potential issues early, avoiding costly repairs or replacements. Understanding power quality metrics allows you to select an inverter that best meets your specific needs. By comparing these metrics, you’ll choose a pure sine inverter that delivers clean, reliable power for your critical applications.

Voltage Accuracy and Stability

Voltage accuracy and stability are essential for ensuring your sensitive devices operate reliably and safely. Fluctuations can cause malfunctions, reduce lifespan, or even damage equipment. When evaluating pure sine inverters or power supplies, look for consistent RMS voltage output close to your mains supply, typically within ±5%. Stability ensures your devices don’t experience sudden dips or surges that disrupt operation. Key aspects include:

- RMS voltage regulation: how closely the output matches the rated voltage

- Voltage fluctuation range: the allowable variation during load changes

- Transient response: how quickly the voltage stabilizes after sudden load shifts

- Peak surge handling: capacity to sustain brief voltage spikes during device startup

Prioritize these metrics to guarantee your equipment receives clean, reliable power, avoiding interruptions or damage caused by unstable voltage.

Harmonic Distortion Levels

Harmonic distortion levels directly impact the quality and reliability of the power output from pure sine inverters. Lower Total Harmonic Distortion (THD) means cleaner, more stable power, ideal for sensitive electronics and precision equipment. High THD causes overheating, electromagnetic interference, and malfunction, especially in medical devices or audio systems. A typical pure sine inverter has THD below 3%, ensuring minimal harmonic content.

| Harmonic Level | Effect |

|---|---|

| Low (<3%) | Cleaner power, less noise, better performance |

| Moderate (3-5%) | Slight distortion, acceptable for most equipment |

| High (>5%) | Increased heat, potential malfunction, EMI issues |

| Very high | Not suitable for sensitive or critical systems |

Common Marketing Claims and How to Evaluate Them

Many marketing claims about pure sine wave inverters can be misleading, making it essential to scrutinize the specifications rather than rely solely on product labels. Labels like “pure sine,” “true sine,” or “utility-grade” often mask quality differences. To evaluate claims accurately, look beyond marketing language and check key specs:

- Total Harmonic Distortion (THD): Aim for less than 3% for true pure sine performance.

- Voltage regulation and frequency stability: Ensure consistent output under varying loads.

- Surge and peak ratings: Verify they can handle motor startup currents.

- Waveform details: Request waveform screenshots or detailed technical datasheets to confirm the shape matches true sine wave characteristics.

Focusing on these parameters helps you avoid overpaying for marketing hype and ensures the inverter meets your actual needs.

Choosing the Right Power Source for Different Applications

Selecting the appropriate power source depends on your specific application and the types of devices you’ll run. For sensitive electronics like medical equipment, telecom gear, or precision instruments, choose a pure sine inverter with low THD (<3%) and stable voltage to guarantee reliable operation and minimal noise. Motor-driven loads such as pumps, compressors, or variable-speed motors perform better with pure sine power, starting easier and running cooler. For basic appliances like heaters, incandescent lighting, or simple chargers, a modified sine source often suffices, saving costs. Portable or emergency setups may accept modified sine inverters if budget or weight is critical. Always match the inverter’s surge capacity to startup currents and verify technical specs rather than relying solely on marketing labels. Proper selection enhances performance and protects your equipment.

Cost vs. Performance: Making an Informed Decision

Balancing cost and performance when choosing a power inverter requires careful consideration of your specific needs and budget. If you have sensitive electronics or motor loads, investing in a pure sine inverter guarantees reliable, low-distortion power. However, for simple appliances like heaters or LED lights, a modified sine inverter can save money without sacrificing function.

Evaluate these factors:

- The importance of clean power for your devices

- Budget constraints and long-term reliability

- Peak surge requirements for motors and compressors

- The total harmonic distortion (THD) and efficiency ratings

Choosing the right inverter depends on aligning performance with your application’s demands. Prioritize critical needs over marketing buzzwords, and always check specifications rather than relying solely on labels.

Frequently Asked Questions

How Can I Verify a Pure Sine Wave Inverter’s Actual Waveform Quality?

You can verify a pure sine wave inverter’s waveform quality by measuring its Total Harmonic Distortion (THD) with a waveform analyzer or oscilloscope. Check the datasheet for THD ratings; look for values below 3% for high-quality outputs. Also, review waveform screenshots or videos. Comparing these measurements against manufacturer specs helps guarantee the inverter truly produces a clean, smooth sine wave, rather than a stepped or distorted signal.

What Are the Typical THD Levels for High-Quality Pure Sine Inverters?

You’ll find that high-quality pure sine inverters typically have THD levels below 3%. This means their output closely mimics utility power, reducing noise and harmonic distortion. When shopping, look for units with THD ratings under 3% for sensitive electronics or audio-visual equipment. Lower THD guarantees cleaner power, safer operation, and less heat generation, making it ideal for critical applications. Always check the datasheet to confirm the actual THD, not just marketing claims.

Can Modified Sine Inverters Power All Types of Sensitive Electronics Safely?

Modified sine inverters can’t safely power all sensitive electronics. Devices like medical equipment, telecom gear, and audio systems require clean, stable power to function correctly. The stepped waveform causes electrical noise, higher harmonic distortion, and potential malfunctions. While some low-power or simple electronics may tolerate it, always check device specifications. For critical or sensitive electronics, a pure sine inverter provides the necessary clean, consistent power, ensuring safety and excellent performance.

Are There Specific Standards or Certifications for Pure Sine Wave Inverters?

Yes, there are specific standards and certifications for pure sine wave inverters. You should look for certifications like UL 458, UL 1741, or CSA for safety, performance, and quality assurance. These verify the inverter meets strict electrical and safety requirements. Always check the datasheets for THD levels, surge ratings, and voltage stability, rather than relying solely on marketing claims. Certified inverters guarantee reliable operation for sensitive electronics and critical applications.

How Does Surge Capacity Differ Between Pure Sine and Modified Sine Inverters?

You’ll find that pure sine inverters typically offer higher surge capacity compared to modified sine models, often designed to handle inrush currents from motors and compressors. Pure sine units usually specify surge ratings that can support starting loads for sensitive electronics and heavy-duty appliances, while modified sine inverters may have lower surge specs, risking insufficient power during startup. Always verify the surge wattage ratings to ensure your equipment’s needs are met.

Conclusion

So, next time you’re dazzled by a shiny pure sine wave promise, remember—unless you’re powering sensitive equipment or dreaming of a silent, smooth ride, it’s probably just fancy marketing. Save your cash for something truly worthwhile, like a good coffee or a new gadget. After all, who needs perfect waveforms when you can settle for a slightly rebellious, modified sine wave that gets the job done—most of the time? Stay savvy, power wisely!