Inline fuse holders come in various styles, from weatherproof automotive types to compact designs for electronics. To guarantee safety, you must choose the right style for your environment and match it with the correct fuse rating and wire gauge. Watch out for common failure points like poor connections, corrosion, and loose wiring, which can cause overheating or shorts. Keep learning how to make the safest, most reliable choices for your circuits.

Key Takeaways

- Inline fuse holders come in various styles tailored for automotive, electronics, indoor, and outdoor applications, with features like waterproofing or compact design.

- Common failure points include loose wiring, corrosion, incorrect fuse ratings, and poor contact quality, leading to overheating or electrical faults.

- Choosing the right style depends on environmental conditions, ensuring features like waterproofing or secure connections for safety and durability.

- Proper installation practices—tight wiring, correct polarity, and matching fuse ratings—are essential for reliable circuit protection.

- Regular inspection and maintenance help identify wear, corrosion, or damage, preventing failure points and ensuring safe operation.

An inline fuse holder is a vital component that protects your electrical circuits from overcurrent damage. When you’re setting up or repairing a system, choosing the right fuse holder ensures your circuit protection is reliable and effective. Proper installation is key; incorrect placement or connection can compromise safety and cause equipment failure. To get it right, pay close attention to installation tips—make sure your wires are clean, stripped properly, and securely connected to avoid loose contacts that can lead to overheating or shorts.

Selecting and properly installing the right inline fuse holder is essential for reliable circuit protection and safety.

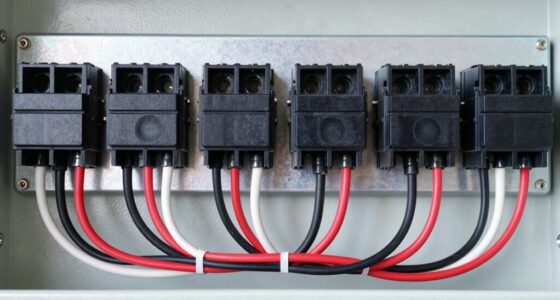

There are various styles of inline fuse holders, each suited for different applications. Some are designed for automotive use, featuring weatherproof casings for outdoor or harsh environments. Others are compact and intended for small electronics or hobby projects. The choice depends on your specific needs, but regardless of style, the fuse holder must match the fuse rating and wire gauge. Using an incompatible fuse or holder can result in insufficient circuit protection or nuisance blows, which you want to avoid.

When considering styles, think about the environment where your circuit will operate. For outdoor setups or vehicles, a sealed or waterproof fuse holder is a safe choice. For indoor or controlled environments, a simple plastic or snap-in style might suffice. The key is ensuring the fuse holder’s design helps prevent accidental disconnections and provides solid contact to avoid intermittent connections. Good contact points and high-quality materials reduce failure points that might cause overheating or electrical faults.

Failure points in inline fuse holders often stem from poor connections, corrosion, or using the wrong fuse ratings. Loose wiring can create resistance, leading to heat buildup and potential failure. Corrosion, especially in exposed environments, can weaken contact points, resulting in unreliable circuit protection. Using the correct fuse rating is essential; too high, and it won’t protect your circuit properly, too low, and it might blow unnecessarily, disrupting your system. Regular inspection and maintenance can help catch these issues before they cause damage.

Choosing a safe and reliable inline fuse holder means prioritizing quality and proper installation. Follow the manufacturer’s instructions carefully—secure your wires tightly, ensure proper polarity, and verify fuse ratings match your circuit’s requirements. Double-check connections after installation and periodically inspect for signs of wear or corrosion. When installed correctly, an inline fuse holder offers a simple yet effective way to safeguard your electrical system, preventing costly damage and ensuring your setup runs smoothly. Remember, circuit protection isn’t just about the fuse itself—it’s about how well your fuse holder is installed and maintained to keep your electrical system safe and functional. Proper circuit protection can extend the lifespan of your equipment and provide peace of mind during operation.

Frequently Asked Questions

How Do I Choose the Right Fuse Holder for My Project?

To select the right fuse holder for your project, consider fuse holder materials like durable plastics or metals for safety. Guarantee it matches your fuse’s size and amperage. Follow installation best practices by securely mounting the holder, keeping wiring neat, and avoiding stress points. Look for quality features such as proper contact resistance and safety certifications. This approach helps ensure reliable protection and safe operation for your electrical setup.

Can Inline Fuse Holders Be Used in High-Temperature Environments?

Sure, you can use inline fuse holders in high-temperature environments—if you enjoy risking meltdowns and circuit failures. Just check the temperature ratings and material selection carefully. Opt for holders made from heat-resistant materials like high-grade plastics or ceramics, and verify their ratings surpass your environment’s temps. Otherwise, you might end up with a fuse holder that’s more toast than your breakfast. Stay safe, or burn out trying!

What Are Common Signs of a Failing Fuse Holder?

You’ll notice signs of a failing fuse holder through visual damage like cracks, burns, or melting around the terminals. Corrosion buildup can also indicate issues, leading to poor electrical contact or increased resistance. If you see these signs, it’s essential to replace the fuse holder promptly to prevent potential electrical failures or safety hazards. Regular inspection helps catch problems early before they cause more serious damage.

Are There Waterproof Inline Fuse Holder Options Available?

Yes, waterproof inline fuse holder options are available. These fuse holders feature a waterproof design that protects the fuse and wiring from water intrusion, making them ideal for outdoor or wet environments. They also offer corrosion resistance, guaranteeing durability over time. By choosing these waterproof fuse holders, you guarantee a safer, more reliable electrical connection that withstands harsh conditions and minimizes the risk of failure.

How Often Should I Inspect and Replace Fuse Holders?

Think of your fuse holder as a crucial guardrail on a busy road—its integrity keeps everything safe. You should inspect your fuse holder every 6 to 12 months, checking for corrosion, cracks, or loose connections. Replacement frequency depends on usage and environmental conditions; if you notice any damage or wear, replace it immediately. Regular inspections ensure your electrical system stays protected and functions reliably.

Conclusion

Choosing the right inline fuse holder is like finding a sturdy anchor amidst a storm—solid, reliable, and built to withstand the unpredictable. By understanding the styles and common failure points, you arm yourself with the knowledge to make a safe, confident decision. Think of it as crafting a resilient bridge over turbulent waters, ensuring your circuits stay protected and your journey remains smooth. When you prioritize safety, you set the stage for a journey free of unexpected breakdowns.