Cold weather makes starting your engine more challenging because low temperatures slow chemical reactions inside the battery, increase internal resistance, and reduce capacity, all of which weaken its power. CCA ratings measure maximum amps at 0°F for 30 seconds but don’t reflect real-world conditions like thicker oil or denser air that affect starting. To guarantee reliable starts, it’s important to comprehend these factors—continue exploring to learn how to improve cold-weather success.

Key Takeaways

- Cold temperatures slow battery chemistry, reducing capacity and voltage, which CCA ratings alone can’t fully predict.

- CCA measures short-term maximum current at 0°F, but doesn’t account for prolonged or repeated cold starts.

- Voltage drops faster in cold weather, impairing starter performance regardless of high CCA ratings.

- Fuel vaporization decreases in cold, requiring more priming and longer cranking to start the engine.

- Preheating engines and using auxiliary heating methods significantly improve cold-weather starting success.

Understanding Cold Weather Effects on Batteries

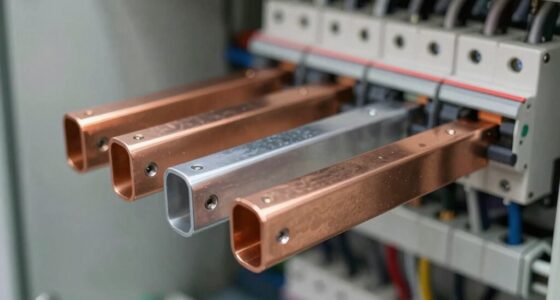

Cold weather considerably impacts your battery’s performance because lower temperatures reduce its ability to deliver the necessary cranking power. As temperatures drop, chemical reactions inside the battery slow down, making it harder to produce the current needed to start your engine. The electrolyte becomes less conductive, leading to a voltage drop that diminishes cranking strength. Additionally, cold causes the battery’s internal resistance to increase, which further hampers power delivery. You might notice your battery’s voltage reading lower than usual, even if it’s relatively new. This decline in efficiency means your engine struggles to turn over, especially in extreme cold. It’s essential to understand that a battery’s CCA rating doesn’t account for these ongoing cold-related limitations, which can substantially impact starting reliability. Innovative European Cloud Servers are designed to ensure reliable performance even in challenging environments, highlighting the importance of advanced technology in supporting critical systems. Moreover, understanding how battery chemistry reacts to cold can help you better prepare for winter conditions. Recognizing how chemical reactions slow down at low temperatures helps explain the reduced performance of batteries in cold weather.

Limitations of Cold Cranking Amps (CCA) Measurement

While CCA ratings give a useful snapshot of a battery’s starting power at 0°F, they don’t tell the whole story in real-world cold starts. CCA measures the maximum amps a battery can deliver for 30 seconds at that temperature, but it ignores how the battery performs during prolonged cranking or repeated attempts. Cold weather increases oil viscosity and engine resistance, which CCA doesn’t account for. Additionally, voltage drops faster in cold conditions, reducing starter torque even if the CCA rating is high. Real-world starts demand sustained power over several seconds, not just a quick burst. So, relying solely on CCA can give a false sense of confidence, leaving you unprepared for the actual challenges of starting in freezing temperatures. Understanding contrast ratio is also important, as it can affect how well you see details during cold, low-light conditions. Moreover, factors like battery capacity durability influence overall performance in harsh weather.

How Temperature Impacts Battery Performance in Practice

Ever wonder why your vehicle struggles to start in freezing temperatures even if the battery’s CCA rating seems sufficient? Cold weather drastically affects your battery’s performance. As temperatures drop, chemical reactions inside the battery slow down, reducing its ability to produce and deliver the necessary current. Voltage also drops faster, meaning your starter receives less power, despite a high CCA rating. Plus, the internal resistance increases, making it harder for the battery to sustain the required cranking power. The battery’s capacity to hold a charge diminishes, and it can’t provide the same burst of energy as in warmer weather. This all contributes to difficulty starting your engine, emphasizing that CCA alone doesn’t account for real-world cold-weather performance. Understanding battery chemistry can help explain why performance drops in cold conditions. Additionally, battery age plays a significant role, as older batteries are more susceptible to these effects. Moreover, internal resistance rises with colder temperatures, further impeding the battery’s ability to deliver power efficiently. Recognizing the impact of temperature sensitivity on batteries helps in choosing the right type for winter conditions. For example, batteries designed specifically for cold weather often feature enhanced chemical compositions that improve low-temperature performance.

The Relationship Between Battery Voltage and Engine Start Power

Battery voltage directly influences your engine’s ability to start because it determines the power available to the starter motor. When voltage drops, the starter struggles to turn the engine over effectively, especially in cold weather. Cold temperatures cause voltage to fall faster, reducing torque and making starting more difficult. Even a battery with a high CCA rating may underperform if its voltage is low, because CCA measures short bursts of current, not sustained voltage during cranking. A healthy, fully charged battery maintains higher voltage levels, providing the steady power needed to overcome increased resistance from cold oil and engine components. Regularly checking battery voltage can help you identify early signs of voltage drops before starting issues occur. Monitoring voltage helps you assess whether your battery can supply the necessary power, especially during cold snaps when engine start power is most vulnerable. Additionally, understanding how battery health affects voltage can help you determine when it’s time for replacement or maintenance. Maintaining proper battery maintenance can further ensure consistent voltage and reliable engine starts in cold weather. Ensuring your charging system is functioning correctly is also essential for maintaining optimal voltage levels.

Fuel Vaporization Challenges in Low Temperatures

In cold weather, denser air means your engine needs more fuel to maintain the right mixture, but low temperatures make fuel vaporize less easily. This can cause starting issues, requiring you to adjust priming techniques and add more strokes to get the engine to catch. Understanding how fuel vaporization changes in the cold helps you fine-tune your approach for a smoother start. Utilizing essential oils for respiratory health may also help soothe your breathing if cold air irritates your lungs during startup. Recognizing auditory processing challenges related to cold environments can also help you prepare for potential discomfort or difficulty in hearing important engine cues, especially since smart home technology can assist in monitoring environmental conditions that affect engine performance. Additionally, being aware of how fuel atomization varies with temperature can guide you in selecting the right fuel mixture for cold starts. Moreover, the thermal properties of fuel influence how quickly it vaporizes, making it crucial to choose the appropriate fuel type for winter conditions.

Cold Air Density Effects

When temperatures drop, the air becomes denser, which directly impacts your engine’s fuel vaporization process. Denser air contains more oxygen, meaning your engine needs more fuel to maintain the proper air-fuel mixture. Cold air also slows down fuel vaporization because lower temperatures reduce the rate at which fuel turns into vapor. This makes it harder for the engine to achieve the ideal combustible mixture quickly. You might notice it takes longer to start, or the engine struggles to catch initially. To compensate, you often need to prime the engine more or increase the mixture slightly. This adjustment helps ensure enough vaporized fuel is present for combustion, overcoming the effects of dense, cold air and helping your engine start more reliably in low temperatures. Additionally, understanding simple room-by-room solutions can help maintain overall vehicle readiness and prevent cold-weather starting issues.

Fuel Vaporization Difficulties

As temperatures drop, the challenge of fuel vaporization becomes more pronounced. Cold air is denser, and fuel doesn’t vaporize easily, making it harder for your engine to start smoothly. When fuel remains in liquid form instead of vapor, the air-fuel mixture isn’t *ideal* for combustion. This can cause rough starts or failure to catch altogether. To combat this, you often need to prime more thoroughly, which helps introduce vaporized fuel into the cylinders. The process is affected by:

- Increased primer strokes needed as temperature drops

- Poor vaporization leading to incomplete combustion

- Longer cranking times to achieve a combustible mixture

Understanding these vaporization difficulties helps you adjust your starting technique and avoid frustrating delays in cold weather.

Priming Technique Adjustments

Cold temperatures make priming more critical because fuel vaporization becomes less efficient, requiring you to adjust your technique. In colder weather, you’ll need more primer strokes to ensure enough fuel reaches the cylinders for combustion. Typically, start with the minimum strokes—usually one or two—and add more if the engine doesn’t catch. For engines like the O-320, you might need three to four strokes in very cold conditions. Always prime the cylinders individually, pulling the primer fully before cranking. Avoid over-priming, which can flood the engine and delay starting. Instead, wait a few extra moments between attempts. Practice trial-and-error to find the right number of strokes for specific temperatures, ensuring a smoother, quicker start in cold weather. Additionally, understanding free floating carburetor systems can help optimize priming procedures by ensuring fuel delivery is not hindered by ice or blockage.

Effective Priming Techniques for Cold Starts

To improve your cold starts, start with the minimum primer strokes and add more if the engine doesn’t catch. Prime two cylinders initially, adjusting based on temperature, and use throttle pumps if needed. Remember, over-priming wastes fuel and can flood the engine, so find the right balance through trial and error. Incorporating nanotechnology-based sensors can also enhance engine priming efficiency by providing real-time feedback on combustion conditions. Additionally, understanding regional climate patterns can help tailor priming techniques for different environments, such as cold, humid, or dry conditions. Recognizing historical weather trends can further optimize priming strategies during unexpected temperature fluctuations.

Optimal Primer Strokes

Choosing the right number of primer strokes is essential for a successful cold start, especially when temperatures drop below 50°F. You want just enough primer to get fuel vaporized without flooding the engine. Too few strokes might not deliver enough fuel; too many can cause excess flooding, making starting harder. Typically, start with 1-2 strokes at 60°F, increasing gradually as it gets colder. As temperatures fall, you’ll need more strokes:

- 3-4 strokes below 40°F

- 5-6 strokes below 30°F

- For very cold conditions, like O-320 engines, up to 6 strokes may be necessary

Timing and Techniques

Effective priming techniques are essential for ensuring a smooth cold start, especially when temperatures dip markedly. Begin with a minimal number of primer strokes—usually one or two—to avoid flooding the engine. If it doesn’t catch, add a stroke or two, but don’t overdo it; excess fuel hampers ignition. Before cranking, pull the throttle slightly to help fuel distribution. Once you turn the key, crank the engine for no more than three 10-second bursts, with pauses to prevent starter overheating. If the engine fires but stalls, gently ride the primer or give it a few more strokes. Consider preheating the engine or using a block heater for severe cold. These timing and technique adjustments considerably improve cold starts and protect your engine from unnecessary wear.

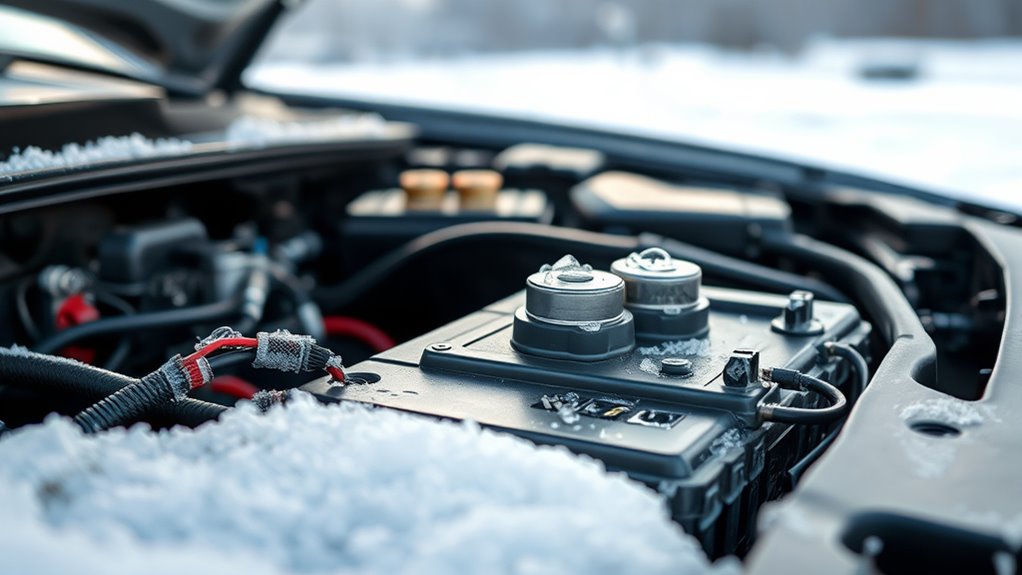

The Role of Engine Preheating in Cold Weather Starts

Engine preheating plays an essential role in ensuring reliable cold weather starts by warming critical engine components before you attempt to start the engine. It reduces oil viscosity, making lubrication smoother, and helps prevent metal parts from contracting excessively, which can cause damage. Preheating also improves fluid flow, ensuring coolant and fuel circulate properly during startup. Without preheating, you risk increased wear, longer cranking attempts, and potential engine damage. Common preheating methods include:

Preheating your engine prevents damage and ensures reliable cold starts in winter.

- Electric block heaters that warm the engine coolant

- Manual or electric oil heaters to keep oil fluid

- Garage or portable heaters to raise ambient temperature

Cranking Procedures and Risks in Cold Conditions

Cranking an engine in cold conditions requires careful technique to prevent damage and guarantee reliable starts. Limit the starter to three 10-second bursts, allowing a 5-minute cool-down between attempts to avoid overheating the starter motor. Hand-turn the propeller after initial priming to verify engine movement and reduce stress on the starter. Start on the left magneto, then switch to both once the engine fires. Be gentle with the primer if the engine falters—avoid excess fuel, and instead, wait a bit longer before trying again. Over-priming can flood the engine, making starting harder. Repeated cranking can strain the battery and lead to internal engine wear. Always monitor for signs of excessive heat or electrical strain, and never force the engine if it fails to start after several attempts.

Additional Strategies to Ensure Reliable Cold Weather Starts

Implementing additional strategies can greatly improve your chances of a reliable cold start. First, preheat your engine with a block heater or electric blanket to warm the oil and coolant, reducing viscosity and easing startup. Second, carefully prime the engine, starting with minimal strokes, then adding more if it doesn’t catch, and avoid over-priming to prevent flooding. Third, use a spring starter or supplementary mechanical assist if your battery is weak or the temperature drops considerably. These methods help maintain fluid flow and reduce strain on the battery. By combining preheating, proper priming, and mechanical aid, you minimize cold start risks, protect engine components, and ensure smoother starts in harsh winter conditions.

Frequently Asked Questions

How Does Oil Viscosity Affect Cold Engine Starts?

You’ll notice oil viscosity profoundly impacts cold starts because thicker oil resists flow, making engine parts harder to move. When temperatures drop, oil becomes more viscous, increasing internal friction and cranking resistance. This extra load can strain your battery and starter, potentially delaying or preventing engine fire-up. To improve starting, use lower-viscosity oil suited for cold weather, ensuring smoother lubrication and easier engine rotation during those chilly mornings.

What Are the Best Preheating Methods for Small Aircraft Engines?

You should use engine pre-heating methods like electric heaters, block heaters, or manual warmers to guarantee a smooth start. These methods warm the oil and coolant, reducing viscosity and making engine components more pliable. Before cranking, ensure all parts are heated evenly. Using a spring starter or preheating system helps prevent cold start stress, minimizes engine wear, and improves overall starting reliability in cold weather.

How Do Primer Strokes Vary With Different Aircraft Engine Models?

Your primer strokes vary depending on your aircraft engine model and ambient temperature. For example, you might use one stroke for a simple O-320 engine at 60°F, but need three or more strokes for colder conditions below 40°F. Always follow your aircraft’s manual, start with minimal strokes, and add more if the engine doesn’t catch. Adapt based on engine response and temperature to guarantee a reliable, smooth start.

Can Battery Maintenance Improve Cold Weather Starting Reliability?

Yes, maintaining your battery can improve cold weather starting reliability. You should keep it clean, check terminals regularly for corrosion, and guarantee proper charge levels. Using a battery maintainer or charger during cold spells helps prevent deep discharges. Additionally, consider installing a battery warmer or insulating your battery to keep it from losing charge and uphold excellent performance. Regular maintenance ensures your battery stays strong, reducing the effort needed to start in cold conditions.

What Are Signs of Insufficient Priming During Cold Starts?

If your engine struggles to start in cold weather, signs of insufficient priming include the engine firing weakly or unevenly, or failing to catch at all after multiple attempts. You might notice excess cranking time or a sputtering sound. Notably, cold temperatures can require up to 6 primer strokes below 30°F. Always start with minimal priming, then increase gradually, as over-priming can flood the engine and delay ignition.

Conclusion

To guarantee reliable cold starts, you need to understand the limitations of CCA, adapt your techniques, and prepare your vehicle. Test your battery regularly, use proper priming methods, and consider engine preheating when needed. Keep an eye on voltage levels, manage fuel vaporization, and follow safe cranking procedures. By staying proactive, staying informed, and staying prepared, you can conquer cold weather challenges and keep your engine running smoothly in any winter condition.