If your equipment shows signs like vibrations, jerky movement, or occasional stalls, it might seem electrical, but it could be belt slip caused by loose, worn, or misaligned pulleys. These mechanical issues often mimic electrical faults like motor stalls or irregular operation. Carefully inspect belt tension and pulley alignment to rule out slipping. Maintaining proper tension and alignment can prevent these confusing symptoms, and you’ll discover more tips to identify and fix the root cause.

Key Takeaways

- Belt slipping can cause irregular machine movements and vibrations that mimic electrical motor faults.

- Visible belt slack or jumping off pulleys may resemble electrical issues like motor stalling.

- Excessive belt tension or misalignment can produce unusual noises similar to electrical malfunctions.

- Mechanical signs such as wear or damage on belts often appear like electrical component failures.

- Both mechanical and electrical problems may cause similar operational symptoms, requiring careful inspection to differentiate.

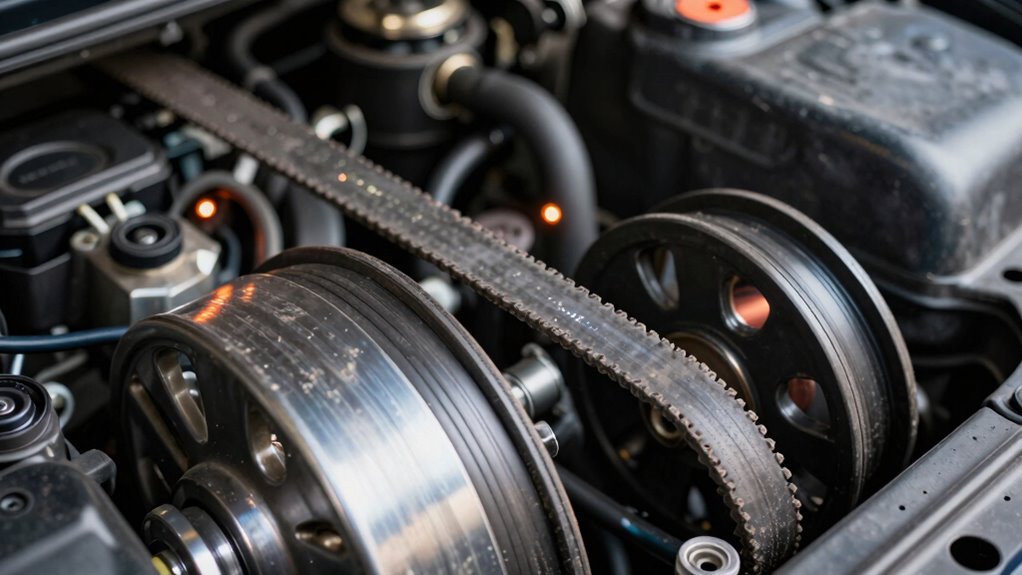

Belt slip symptoms often indicate that your machine isn’t functioning properly and needs immediate attention. If you notice belts slipping, it can mimic electrical problems, but the root cause is often mechanical. One of the first things to check is the tension adjustment. If the belt isn’t tight enough, it won’t grip the pulleys properly, leading to slipping and inconsistent operation. You should verify the belt is snug but not overly tight, as excessive tension can cause premature wear of both the belt and pulleys. Adjusting the tension requires loosening the mounting bolts, repositioning the belt, and tightening it to the manufacturer’s specifications. Proper tension minimizes slipping and extends the lifespan of your belt and other components.

Another critical aspect to contemplate is pulley alignment. Misaligned pulleys create uneven tension across the belt, which can cause it to slip, vibrate, or even jump off the pulley altogether. You can check pulley alignment visually by observing if the pulleys are in the same plane or use a straightedge or laser alignment tool for more precision. Correcting pulley alignment involves loosening the pulley mounting bolts, adjusting their position until they are properly aligned, and then tightening them securely. When pulleys are aligned correctly, the belt maintains even contact with the pulleys’ surfaces, reducing slipping and preventing the false impression of electrical issues like motor faults or wiring problems. Additionally, proper maintenance practices can help prevent future belt slip symptoms and keep your machinery running smoothly.

It’s easy to mistake belt slip symptoms for electrical malfunctions because both can cause similar symptoms like irregular operation, motor stalling, or inconsistent power delivery. However, mechanical issues tend to manifest as physical signs, such as visible slack or misalignment, whereas electrical problems often involve unusual noises, sparks, or error codes. Regularly inspecting your belts and pulleys, especially when you notice performance issues, can save you time and money by catching problems early. If adjusting tension and pulley alignment doesn’t resolve the slipping, then it’s wise to rule out electrical causes, but often, these mechanical adjustments do the trick.

Frequently Asked Questions

Can Belt Slip Cause Engine Overheating?

Yes, belt slip can cause engine overheating. When your belt has improper tension or pulley misalignment, it can slip, reducing the efficiency of the cooling fan and water pump. This decreased performance hampers heat dissipation, leading to engine overheating. Regularly check your belt tension and pulley alignment to prevent slipping, ensuring your cooling system functions properly and keeps your engine at a safe temperature.

How Often Should I Check Belt Tension?

You should check your belt tension every 10,000 miles or at least twice a year—ironic, isn’t it? Proper inspection frequency keeps your engine running smoothly and prevents those sneaky slip-ups that mimic electrical issues. Don’t wait for strange noises or overheating signals; regular belt tension checks are your best defense. So, make it a habit and save yourself from unexpected breakdowns and costly repairs down the road.

Are There Specific Signs for Belt Wear?

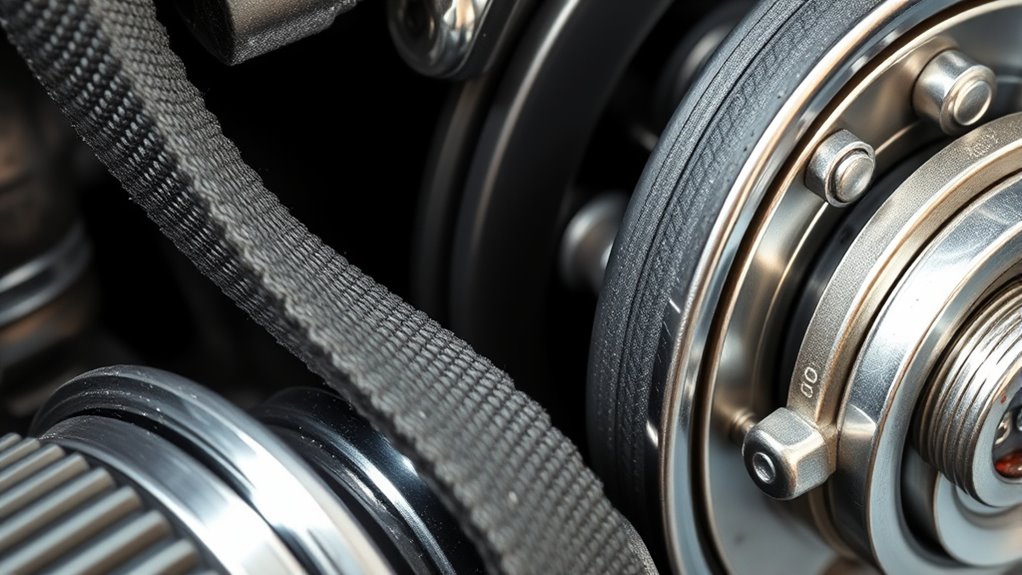

Yes, there are specific signs for belt wear. You should check for cracks, fraying, or glazing on the belt’s surface. Also, examine belt alignment to ensure it runs straight and isn’t misaligned, which can cause uneven wear. Additionally, inspect pulley condition, as damaged or worn pulleys can accelerate belt deterioration. Regularly monitoring these signs helps prevent slipping and maintains ideal performance.

Can Belt Slip Affect Vehicle Fuel Efficiency?

Yes, belt slip can reduce your vehicle’s fuel efficiency. When the belt lacks proper tension or the pulley is misaligned, it slips more often, causing the engine to work harder. This extra effort burns more fuel and impacts performance. Regularly check your belt tension and pulley alignment to prevent slipping, ensuring your engine runs smoothly and efficiently. Proper maintenance keeps your vehicle running at its best.

What Tools Are Needed to Inspect Belts?

You need a few essential tools for belt inspection, including belt inspection tools like a flashlight and a mirror to check for cracks or wear, and a tension gauge to measure proper belt tension. Use the tension gauge to guarantee the belt isn’t too loose or tight, which can cause slip. These tools help you visually and physically assess the belt’s condition, preventing potential issues before they become major problems.

Conclusion

Now, when your belts slip, it might seem like just an electrical issue, but don’t be fooled. The silent warning signs mirror electrical problems, yet the root is mechanical. Ignoring the subtle cues can lead to costly repairs or downtime. Recognize the truth behind the symptoms—sometimes, what looks like an electrical glitch is really a belt slipping silently. Stay vigilant, and you’ll catch the problem before it slips away entirely.