To add new loads without overworking your system, start by evaluating your current power capacity and guaranteeing it includes safety margins for growth. Project future demands and design your system with scalable components and redundancy. Calculate voltage and current needs accurately, then implement load balancing and energy-efficient technologies. Regular maintenance and smart controls help maintain reliability. Keep in mind that optimizing these steps can ensure your system stays safe and efficient—more tips await if you continue.

Key Takeaways

- Analyze current load capacity and include safety margins to accommodate future growth and prevent overloads.

- Plan for scalable infrastructure with extra capacity in transformers, wiring, and switchgear for easy expansion.

- Calculate new load requirements accurately, considering voltage, current, and device specifications, to ensure safe integration.

- Balance loads across circuits and implement power management systems to optimize efficiency and prevent overloading.

- Regularly monitor system performance and conduct maintenance to adapt to changes and maintain reliable, safe operation.

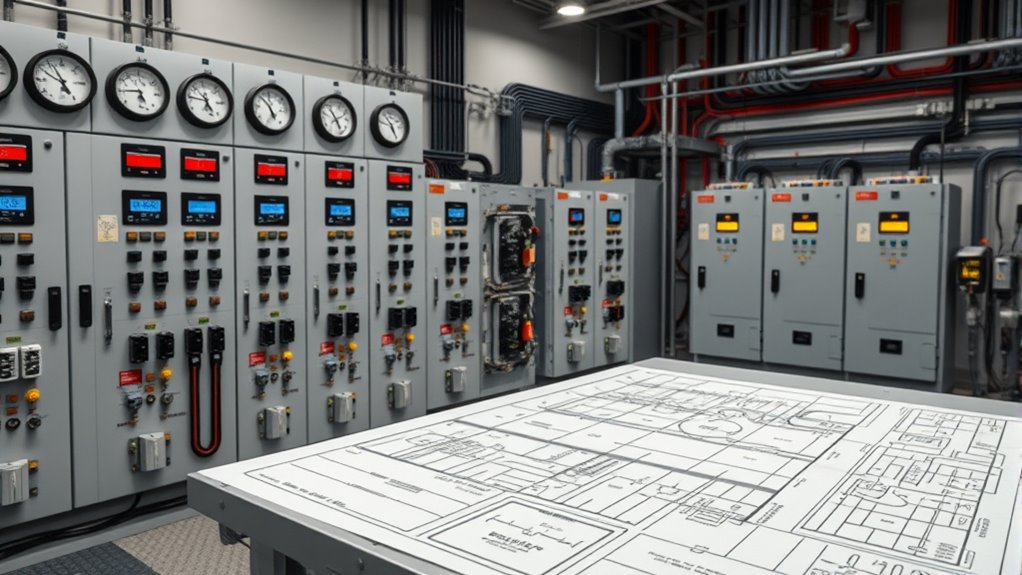

Assessing Current Power Load and Capacity

To effectively assess your current power load and capacity, you need to analyze all operational machinery, equipment, and systems. Start by calculating the electrical load requirements for each component, factoring in appliance ratings, lighting needs, and safety margins. Determine both peak and average loads to ensure your system can handle maximum consumption without overloads. This process helps you identify current energy demands during busy periods and prevents undersizing transformers, switchgear, or circuit breakers. Be sure to include any auxiliary systems that contribute to total load. Accurate load analysis provides a clear picture of your existing capacity, ensuring your power distribution is reliable and efficient. Incorporating power system capacity and performance metrics can further enhance your understanding of energy use in specific environments, especially when evaluating energy efficiency and system reliability. Additionally, reviewing load management strategies can help optimize your system’s performance and prevent overloads during peak times.

Projecting Future Expansion and Load Growth

Planning for future expansion requires you to analyze current growth trends and anticipate changes in equipment and production capacity. Start by reviewing historical data to identify patterns in energy use and machinery upgrades. Consider upcoming projects, new product lines, or increased production targets that could boost loads. Factor in planned equipment additions, automation, or technology upgrades that may alter power demands. Incorporate a safety margin to accommodate unexpected growth or spikes in usage. Design your system with extra capacity in transformers, switchgear, and cabling, ensuring flexibility for scalability. Use modular components that can be easily expanded or reconfigured. Additionally, monitoring systems can help you track and respond to load changes in real-time. Regularly reviewing system capacity and performance data ensures ongoing reliability and efficient operation. Employing load forecasting techniques can further enhance your ability to project future increases accurately. Incorporating predictive analytics can help you identify potential capacity constraints before they become critical. Leveraging capacity planning tools allows for more precise adjustments to your infrastructure, avoiding unnecessary overinvestment. By projecting future load increases accurately, you prevent overloading your system and avoid costly upgrades or downtime down the line.

Analyzing System Architecture for Scalability

Analyzing system architecture for scalability guarantees your power distribution can grow seamlessly with your operations. You need to assess your current setup, identifying how well it supports future expansion. Focus on load centers, transformer placements, and supply line routes to ensure they can handle increased demand. Check if your system includes redundancy, such as multiple utility sources, to maintain reliability during growth. Evaluate how your distribution infrastructure accommodates potential load spikes and redundancy requirements. Incorporate modular components that allow easy upgrades or additions. Consider automation and smart technologies that enhance scalability and control. Additionally, system flexibility plays a crucial role in adapting to changing needs and ensuring long-term reliability. By designing with connected equipment in mind, you’ll ensure your system can adapt without overloading existing components, supporting long-term growth while maintaining safety, efficiency, and reliability. Incorporating scalable infrastructure principles ensures your system remains adaptable and resilient as your power needs evolve. Embracing industry best practices can further optimize your system for future demands. Incorporating insights from sound healing science can also inform the development of systems that promote healthier environments and better user experiences.

Calculating Voltage and Current Requirements for New Loads

To accurately plan for new loads, you need to determine the appropriate voltage levels for each system segment. Next, you’ll calculate the total amperage by summing the connected equipment’s demands, ensuring your wiring and protection devices are sufficient. Don’t forget to include a capacity margin to handle demand fluctuations and future growth reliably. Considering energy efficiency standards can also help optimize your system’s performance and sustainability. Properly assessing load calculations ensures that your system remains safe and efficient under varying conditions. Additionally, understanding filter maintenance and pump protection measures can prevent equipment failures and improve overall system reliability. Regularly reviewing ventilation considerations is essential to maintain safety and optimal operation of your system components.

Voltage Level Determination

How do you determine the appropriate voltage and current requirements when adding new loads to an electrical system? First, identify the voltage level needed for each device or system, considering manufacturer specifications and operational standards. Check the voltage ratings to guarantee compatibility with existing supply levels—whether it’s 120V, 240V, or higher for industrial loads. Next, calculate the current draw based on the equipment’s power requirements, typically using the formula: Current = Power / Voltage. Add safety margins to account for startup surges and future expansion. This step ensures that your wiring, circuit breakers, and transformers can handle the load safely and efficiently. Proper voltage and current determination prevents overloading, reduces equipment stress, and maintains system stability.

Amperage Calculation Method

Calculating the amperage requirements for new loads involves a straightforward process that starts with knowing the power rating of each piece of equipment. To determine current, use the formula: I = P / V, where I is current in amperes, P is power in watts, and V is voltage. This helps you identify how much current each load draws. To visualize, see the table below:

| Equipment Type | Power Rating (W) | Voltage (V) | Current (A) |

|---|---|---|---|

| Lighting Fixture | 100 | 120 | 0.83 |

| Motor | 1500 | 240 | 6.25 |

| Control Panel | 300 | 120 | 2.5 |

Accurate calculations ensure cables and breakers handle loads safely, preventing overloads and system failure. Additionally, understanding amperage capacity helps in selecting appropriate wiring and protective devices to maintain system safety and efficiency. Proper planning can also prevent system overloads by ensuring that the total load remains within safe limits.

Capacity Margin Consideration

When determining the voltage and current requirements for new loads, it’s essential to incorporate a capacity margin to account for future growth and unexpected demand spikes. This margin provides a buffer, ensuring your system can handle sudden increases without overloading. Typically, you add around 10-20% to your calculated load, depending on anticipated expansion. This extra capacity helps prevent voltage drops and equipment stress during peak periods. Consider both short-term fluctuations and long-term growth when setting your margins. Accurate calculations with a safety buffer allow you to select appropriately rated components, such as transformers and circuit breakers. Additionally, understanding the concept of Free Floating can be useful when planning for flexible load configurations. Including a capacity margin ensures your system remains reliable, flexible, and ready for future demands, avoiding costly upgrades or system failures caused by underestimated loads. Well-sourced coverage of these concepts is vital for creating a resilient power plan.

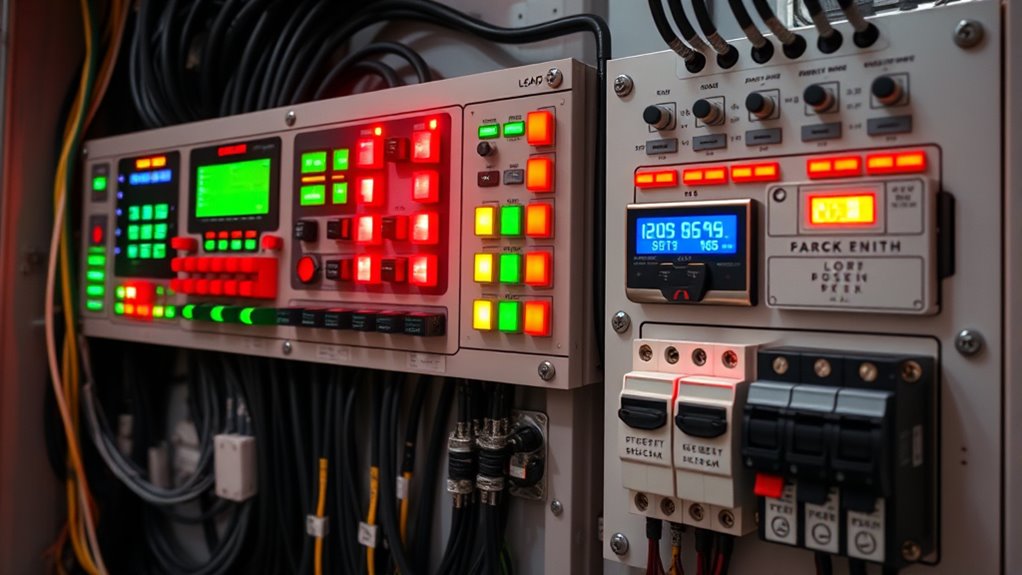

Implementing Load Balancing and Efficiency Measures

Effective load balancing and efficiency measures are essential for optimizing power distribution and reducing operational costs. By evenly distributing loads across circuits, you prevent overloading and minimize system inefficiencies. Incorporate energy-saving technologies like LED lighting, smart controls, and variable frequency drives to cut energy consumption. Use power management systems that monitor and adjust loads in real-time, ensuring ideal operation. Implementing power factor correction devices reduces reactive power and improves overall system efficiency. Regular maintenance and analysis of load patterns help identify areas for improvement. These measures not only lower energy bills but also extend equipment lifespan and enhance system reliability. Focus on integrating scalable, efficient solutions that align with your current and future power needs.

Ensuring Safety and Reliability in Power Distribution

Ensuring safety and reliability in power distribution requires implementing robust design practices that prioritize personnel protection and system stability. You should use proper grounding methods to prevent electrical shocks and minimize interference. Select circuit breakers with appropriate ratings to handle current surges and short circuits, reducing the risk of equipment failure. Maintain clear labeling and organized wiring to facilitate safe maintenance and troubleshooting. Incorporate redundancy by designing multiple supply paths and backup systems like generators or UPS units, ensuring continuous operation during outages. Regular inspections and testing are essential to identify potential issues early. Adhering to safety standards and codes safeguards both personnel and equipment, while reliable system architecture prevents unexpected failures and supports long-term operational stability.

Integrating Automation and Smart Technologies for Load Management

Integrating automation and smart technologies into power distribution enhances load management by providing real-time monitoring and control. With these tools, you can instantly identify overloads, voltage fluctuations, and power quality issues, allowing immediate adjustments. Smart sensors and meters collect data on energy consumption, helping you optimize load distribution across circuits. Automated systems can dynamically balance loads, prevent equipment overloads, and improve efficiency. You can also set up alerts and remote controls, reducing downtime and manual intervention. Incorporating these technologies guarantees your system adapts to changing demands seamlessly. Plus, they support predictive maintenance, reducing unexpected failures. Overall, automation and smart tech streamline load management, improve reliability, and optimize energy use—all essential for handling new loads without overtaxing your system.

Frequently Asked Questions

How Do I Determine the Safety Margins for Added Loads?

You determine safety margins by adding a buffer of about 10-20% to your calculated load requirements. This extra capacity accounts for unexpected demand spikes and future growth. Review equipment ratings and safety standards to make certain your system can handle occasional overloads without risking damage. Regularly monitor system performance and adjust margins as your load increases, maintaining a safe, reliable electrical setup that prevents overloading or failures.

What Are the Best Practices for Integrating Backup Power Sources?

Imagine a safety net catching you when you fall—integrating backup power sources works the same way. You should select reliable generators or UPS systems suited for your load demands, install automatic transfer switches for seamless switching, and make certain proper maintenance. Regular testing keeps everything ready. By planning ahead and designing for quick, smooth transitions, you keep your system resilient and your operations running, rain or shine.

How Can I Minimize Power Quality Issues With New Loads?

To minimize power quality issues with new loads, you should conduct thorough load analysis and guarantee proper system balancing. Use filters, voltage regulators, and surge protectors to reduce fluctuations and transients. Keep wiring and connections secure, and avoid overloading circuits. Additionally, consider upgrading to higher capacity equipment if needed, and maintain regular system inspections. Implementing these measures helps maintain stable voltage, reduce harmonics, and prevent equipment damage.

What Are Cost-Effective Strategies for Future Load Scalability?

You can save costs by designing your system with extra capacity for future growth, including larger transformers and switchgear. Incorporate modular, scalable components that allow easy upgrades. Use demand forecasting to anticipate increased loads and plan accordingly. Implement flexible cabling and backup power solutions, like UPS and generators, to handle growth without overloading. Regularly review and adjust your system to guarantee it remains efficient and prepared for expansion.

How Do I Ensure Compliance With Electrical Safety Standards During Upgrades?

Your safety standards are your shield against electrical hazards, so don’t cut corners. You must follow all local, national, and industry regulations, ensuring proper grounding, circuit protection, and maintenance. Regular inspections and updates are vital, and always use certified equipment. Document every upgrade, and train staff on safety procedures. Think of compliance as your fortress — unwavering, indispensable, and the key to keeping everyone protected when expanding your system.

Conclusion

So, after all that planning, it’s amusing how adding new loads can seem simple—until your system suddenly becomes overwhelmed. Ironically, the more you think you’ve accounted for, the more surprises you’ll find lurking in your wiring. But don’t worry; with careful assessment, smart upgrades, and a little foresight, you’ll keep everything running smoothly—until your next big project, that is. After all, what’s life without a little electrical adventure?