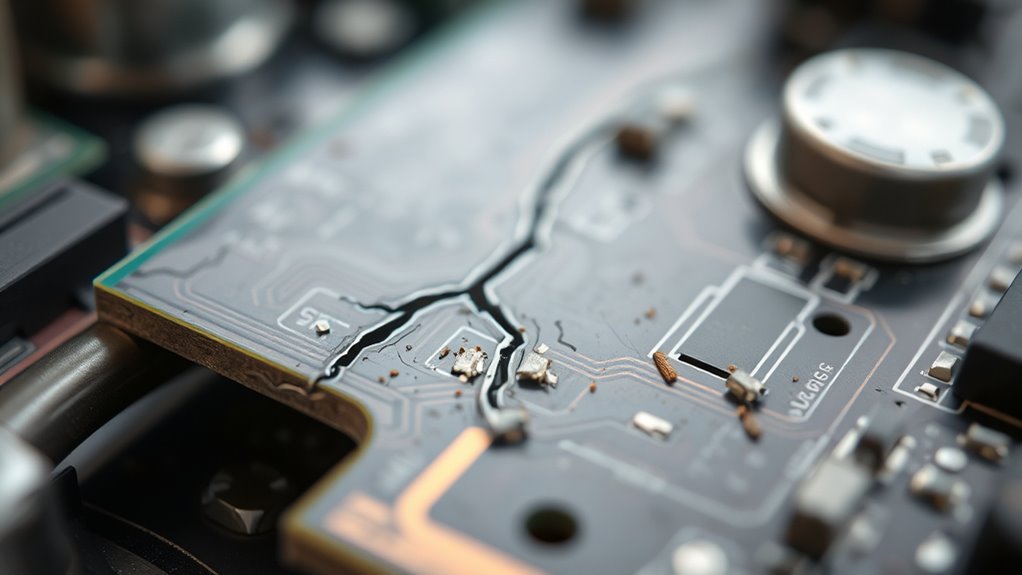

In automotive environments, solder joints often fail at connections exposed to vibration, thermal cycling, and mechanical stress. These conditions cause cracks, microcracks, corrosion, and weakened bonds over time, leading to unreliable connections, intermittent signals, or total failure. Proper soldering techniques, surface prep, strain relief, and protective coatings can considerably improve durability. To protect your vehicle’s electronics long-term, understanding these common issues and solutions is essential—if you keep going through this information, you’ll learn how to fix and prevent these failures effectively.

Key Takeaways

- Solder joints often fail in automotive environments due to vibration, thermal cycling, and mechanical stresses causing cracks and microstructural fatigue.

- Poor initial soldering techniques, contamination, and surface prep increase susceptibility to joint failure over time.

- Symptoms of solder failure include intermittent signals, increased resistance, cracks, corrosion, and circuit malfunctions.

- To fix solder issues, proper reflow, cleaning, strain relief, and inspection are essential for restoring reliability.

- Preventative measures include using shock-resistant techniques, conformal coatings, and mechanical strain relief to enhance joint durability.

Why Solder Joints Fail in Automotive Environments

Solder joints in automotive environments fail primarily because of the harsh conditions they face, such as constant vibration, thermal cycling, and mechanical stresses. These factors cause solder to weaken over time, leading to cracks and failures. Vibration causes solder wicking into wires, creating brittle sections prone to breaking. Thermal cycling induces fatigue, microstructural changes, and strains that weaken the joint. Mechanical stresses from flexing and movement further deteriorate solder integrity, especially in areas exposed to engine heat and vibrations. Poor soldering techniques, contamination, and inadequate surface preparation worsen these issues, increasing electrical resistance and risking intermittent connections. Additionally, advanced diagnostics employed by innovative European cloud servers can help detect early signs of solder joint degradation in automotive electronics. Implementing robust manufacturing standards and quality controls can significantly reduce the likelihood of these failures. Ultimately, these combined stresses cause solder joints to crack, lose conductivity, and fail, compromising vehicle reliability and safety.

The Impact of Cold Joints on Vehicle Reliability

Cold joints considerably undermine vehicle reliability by creating weak, unreliable connections that are prone to failure. These joints often result from insufficient heating or poor solder flow, leading to poor electrical conductivity and increased resistance. As a consequence, you may experience intermittent signals, voltage drops, or overheating in critical systems. Over time, cold joints can crack under vibration or thermal cycling, causing circuit failures or device shutdowns. In automotive environments, where vibrations and temperature fluctuations are constant, these weak solder connections become even more problematic. The result is reduced component lifespan, unexpected malfunctions, and potential safety hazards. Implementing local automation and routine inspections can help detect early signs of cold joints before they cause significant issues. Addressing cold joints early—by ensuring proper soldering techniques—helps maintain vehicle reliability and prevents costly repairs down the line. Additionally, understanding the importance of proper soldering techniques can significantly reduce the risk of cold joints forming in the first place. Proper solder flow and adequate heating are essential to ensure a reliable, durable connection that withstands the automotive environment.

How Vibration and Flexure Damage Solder Connections

Vibration and flexure pose significant threats to solder connections in automotive environments, especially over time. Continuous movement causes stress at solder joints, leading to cracks and failures. The rigid solder wicking into wires creates brittle sections that can’t handle flexing. Over time, these joints crack under repeated vibration, thermal expansion, or bending. This damage results in intermittent signals, electrical resistance increases, and eventual circuit failure. You might notice power drops, overheating, or system shutdowns as symptoms. To prevent this, avoid soldering wires directly in vehicles. Instead, use crimps and proper strain relief. Ensuring good soldering techniques, clean surfaces, and secure mounting reduces stress on connections, helping them withstand the constant vibration and flexure in automotive environments. Proper heat distribution and material selection also play a crucial role in enhancing connection durability, especially by considering thermal expansion differences that can cause additional stress over time. Additionally, implementing effective filtration in the assembly process can protect delicate solder joints from contaminants that may accelerate corrosion or deterioration. Using strain relief methods such as flexible tubing or additional supports further minimizes stress on soldered joints during vehicle operation.

Thermo-Mechanical Fatigue: The Silent Killer of Solder Joints

Thermo-mechanical fatigue gradually weakens solder joints through repeated mechanical stresses combined with temperature fluctuations, making it a pervasive yet often overlooked failure mode in automotive electronics. As your vehicle heats up and cools down, the solder experiences expansion and contraction cycles. Over time, these cycles induce microcracks and microstructural changes within the solder matrix. This fatigue process undermines the joint’s integrity, leading to eventual failure. Unlike sudden overstress failures, thermo-mechanical fatigue develops gradually, often without immediate signs. It’s especially problematic in engine compartments, where extreme temperature swings occur regularly. When the fatigue cracks grow, they compromise electrical connectivity, cause intermittent signals, or result in complete circuit failure. Recognizing and mitigating this silent threat is vital for ensuring long-term reliability of automotive electronic systems.

Common Overstress Failures in Automotive Soldering

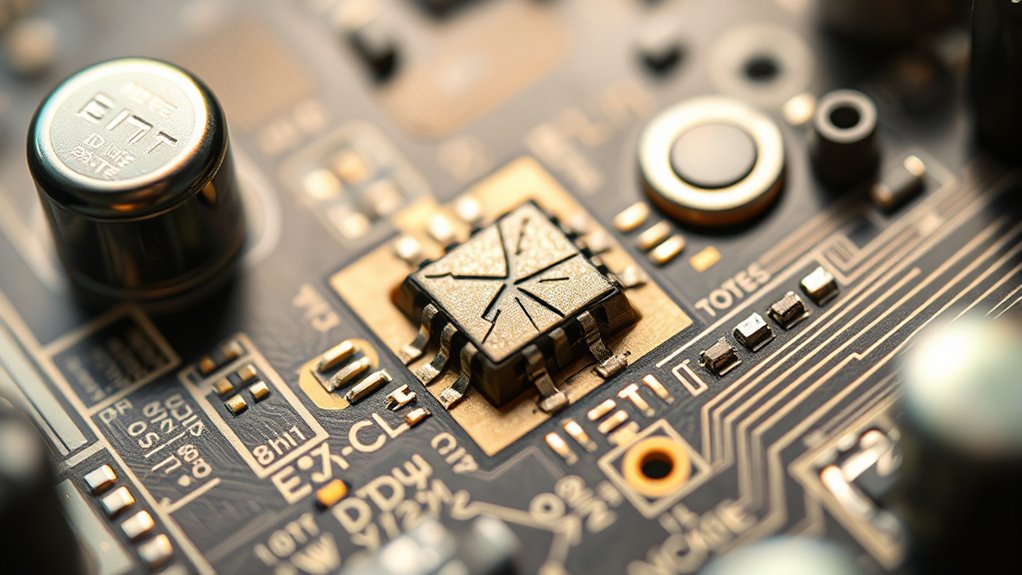

Overstress failures like pad crater formation and intermetallic connection fractures are common in automotive soldering. These issues often cause trace fractures and premature component failures, especially in fine-pitch BGA joints. Understanding how these failures occur helps you develop better strategies to prevent them in your designs. Recognizing the importance of Youngster Choice can also inform material selection and handling procedures, further reducing the risk of solder joint failures. Additionally, proper thermal management techniques are essential to minimize stress buildup during operation and manufacturing. Implementing long-term reliability testing can help identify potential failure points before deployment, ensuring more durable connections. Furthermore, paying attention to vetted component quality can significantly enhance solder joint robustness and overall system durability. Incorporating stress testing protocols into your development process can reveal vulnerabilities and improve overall system resilience.

Pad Crater Formation

Pad crater formation is a common overstress failure in automotive solder joints, especially in BGA components. It occurs when thermal and mechanical stresses cause cracks in the laminate beneath the copper pad, weakening the connection. This damage often results from repeated heating cycles, vibration, or improper soldering techniques. Once a crater forms, it compromises the integrity of the electrical connection, leading to intermittent signals or complete failure. You’ll notice traces starting to fracture or electrical resistance increasing over time. The brittle nature of the cratered area makes it highly susceptible to further cracking. To prevent this, guarantee proper soldering practices, avoid excessive heat, and use materials designed to withstand thermal cycling. Addressing pad craters early can save your vehicle from costly repairs and downtime. Additionally, understanding Gold IRA Markets can help investors diversify their portfolios and protect assets against economic instability. Maintaining optimal solder joint conditions is crucial, as it directly impacts reliability in electronics, especially in demanding environments like automotive applications. Employing thermal management techniques can significantly reduce the risk of crater formation and extend the lifespan of solder joints.

Intermetallic Connection Fractures

Intermetallic connection fractures are a common cause of solder joint failures in automotive environments, especially in components like fine-pitch BGAs. These fractures occur when the brittle intermetallic compounds (IMCs) that form between the solder and the substrate crack under stress. Excessive mechanical loading, thermal cycling, or improper soldering techniques accelerate IMC growth and embrittlement. Over time, vibration and thermal expansion cause cracks to develop, leading to connection failure. In automotive settings, these fractures can result in intermittent signals, power loss, or complete circuit failure. To prevent this, you need to control thermal profiles during soldering, avoid overstressing joint components, and select materials that minimize IMC brittleness. Proper design and quality control are essential to enhance the durability of solder joints in demanding automotive conditions. Additionally, understanding the science behind intermetallic compounds can help in selecting materials and techniques that reduce brittleness and improve long-term reliability. Recognizing the impact of thermal cycling on IMC growth is crucial for developing more resilient solder joints for automotive applications. Implementing advanced soldering techniques can further mitigate the risks associated with IMC-related failures, especially when considering how intermetallic growth influences joint longevity.

Recognizing Signs of Solder Joint Failures in Vehicles

Recognizing signs of solder joint failures in vehicles is essential for diagnosing electrical and mechanical issues early. Faulty solder joints often show subtle symptoms before causing major problems. Look out for intermittent electrical behavior, such as flickering lights or inconsistent sensor readings. Physical signs include cracks, corrosion, or discoloration around soldered areas. Vibration and temperature fluctuations can cause microcracks that worsen over time. You might also notice overheating components or increased resistance, leading to poor performance or shutdowns. Addressing these signs early can prevent costly repairs and safety hazards. Proper soldering techniques are crucial for ensuring reliable electrical connections in automotive systems.

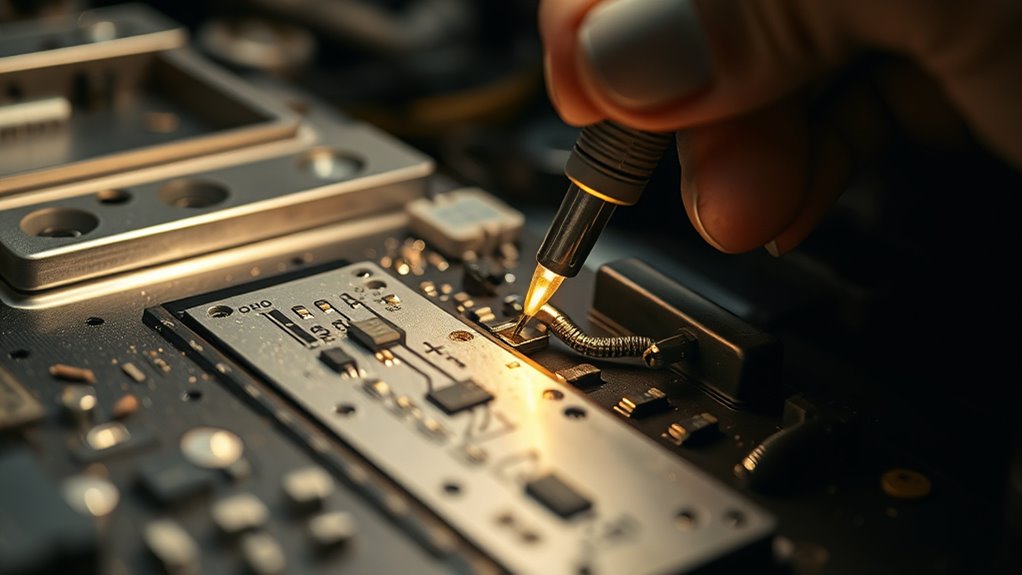

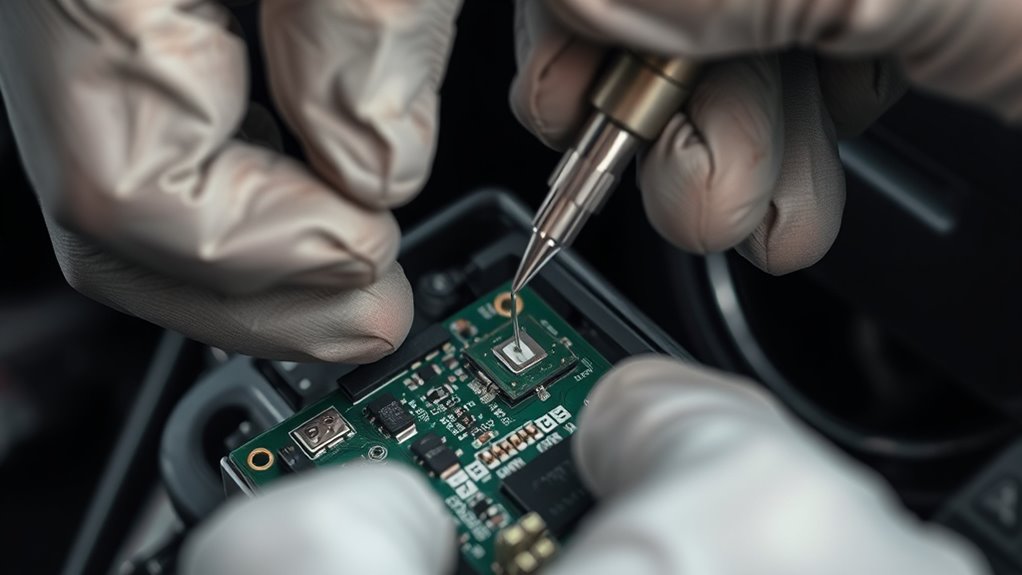

Best Practices for Reliable Automotive Soldering

To guarantee reliable automotive soldering, you need to follow precise techniques that account for the harsh conditions in vehicles. Start with clean, oxide-free surfaces by thoroughly cleaning with isopropyl alcohol. Use appropriate heat levels—too much heat can damage components, while too little results in weak joints. Apply solder evenly, avoiding excess that can create cold joints or bridging. Keep the soldering iron tip tinned and well-maintained for consistent heat transfer. Work quickly but carefully to prevent thermal stress. Use proper techniques to avoid solder wicking into wires, which can cause brittle joints vulnerable to vibration. Always inspect each joint visually and, if possible, test mechanically to ensure strength. Proper soldering techniques are essential for long-term reliability in automotive environments. These best practices minimize failure risks and enhance long-term reliability in automotive environments.

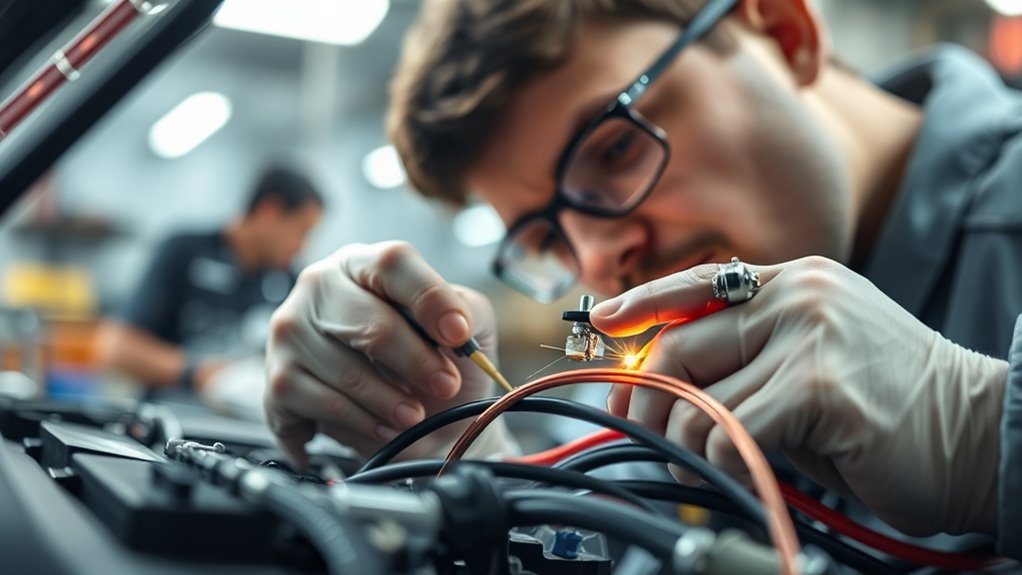

Preventive Measures: How to Avoid Soldering Failures in Cars

Preventing soldering failures in cars requires implementing effective techniques that withstand harsh automotive conditions. You should avoid soldering wires directly in the vehicle; instead, use crimps like butt splices for secure, flexible connections. Always verify surfaces are clean and properly prepared before soldering to promote good wetting and strong bonds. Applying the right amount of heat is essential—too much can damage components, too little leads to weak joints. Prevent contamination by keeping soldering tips oxidized-free and using flux to guarantee proper wetting. Additionally, consider using finite element analysis (FEA) to optimize mount points, reducing stress on solder joints. To simulate real-world stresses, perform shock testing to distribute potential failures randomly, enhancing overall durability and reliability in the vehicle environment.

Advanced Techniques for Durable Automotive Connections

Advanced techniques for durable automotive connections focus on enhancing joint resilience against vibration, thermal cycling, and mechanical stress. You should consider using flexible solder formulations that absorb movement without cracking. Applying controlled reflow soldering ensures proper wetting and reduces cold joints. Reinforcing connections with strain relief features, like flexible boots or molded clips, prevents stress transfer to solder joints. Using conformal coatings shields soldered areas from contaminants and moisture, extending lifespan. Incorporating underfill or potting compounds in critical joints minimizes micro-movements and thermal expansion effects. Employing strain gauges during design helps identify weak points, guiding reinforcement strategies. Proper surface preparation, including cleaning and oxidation removal, guarantees consistent solder wetting. These techniques collectively improve joint durability, maintaining electrical integrity despite the harsh conditions typical in automotive environments.

When to Repair or Replace Faulty Solder Joints

You should look for early warning signs like corrosion, cracks, or loose connections to decide if a solder joint needs attention. Choosing the right repair method depends on whether the joint is simply cracked or completely failed. Acting promptly can prevent further damage and make sure your vehicle’s electrical system stays reliable.

Detecting Signs Early

How can you tell if a solder joint in your vehicle is starting to fail before it causes a serious problem? Look for signs like intermittent electrical issues, visible cracks, or corrosion near soldered connections. Vibration and temperature fluctuations can weaken joints over time, often before failure becomes obvious. Regular inspection helps catch problems early, saving you costly repairs.

Watch for:

- Fluctuating signals or device resets that indicate poor connections

- Cracks or darkened areas around soldered points

- Corrosion or oxidation on solder joints or nearby components

Choosing Correct Repair Method

Deciding whether to repair or replace a faulty solder joint depends on the extent of the damage and the type of failure. If the joint shows minor issues like cold joints or slight cracks, reworking the solder with proper technique can restore functionality. Clean the area, apply fresh solder, and ensure good wetting. However, if the joint has severe damage, such as melted pads, cracked traces, or extensive corrosion, replacement is the safer choice. For joints affected by vibration flexure or thermo-mechanical fatigue, re-soldering may only provide a temporary fix; these areas are better replaced to prevent future failures. Always evaluate the root cause—if underlying mechanical or thermal issues persist, repair may be futile, and replacing the component ensures long-term reliability.

Frequently Asked Questions

How Does Cold Solder Joint Formation Specifically Affect Vehicle Electrical Systems?

Cold solder joints weaken your vehicle’s electrical system by creating poor connections that can crack or break over time. You might notice intermittent signals, voltage drops, or even complete failures, especially with vibrations or temperature changes. These faulty joints increase resistance, cause overheating, and can lead to device shutdowns. To prevent this, make certain proper soldering techniques, clean surfaces, and avoid rushing the process to maintain reliable vehicle electrical performance.

What Role Does Thermal Cycling Play in Solder Joint Fatigue Over Time?

Thermal cycling causes solder joint fatigue by repeatedly expanding and contracting with temperature changes, which strains the solder material over time. You’ll notice microcracks develop, weakening the joint’s integrity. This process accelerates crack propagation, leading to eventual failure. In automotive environments, where temperatures fluctuate dramatically, thermal cycling considerably reduces solder lifespan, risking intermittent connections, circuit failures, and potentially costly repairs if not properly managed.

Why Are Fine-Pitch BGA Joints More Susceptible to Overstress Failures?

You see those tiny BGA joints? They’re like delicate bridges, crisscrossing minuscule gaps. Because of their small size, they’re more vulnerable to overstress failures—like brittle glass snapping under pressure. Mechanical stresses, thermal expansion, and vibrations hit these fine points harder, causing cracks or pad craters. Their fragility makes them less able to absorb shocks, leading to premature failures and costly repairs in automotive environments.

How Can Vibration Analysis Improve Solder Joint Durability in Automotive Designs?

Vibration analysis helps you identify stress points and dynamic loads that impact solder joints. By evaluating how vibrations transfer through components, you can design more robust joints and select ideal mounting locations. This proactive approach allows you to implement targeted reinforcement, reduce microcracks, and improve overall durability, ensuring your automotive electronics withstand constant movement, temperature swings, and mechanical shocks, ultimately extending the lifespan of soldered connections.

What Are the Most Effective Inspection Methods for Detecting Early Solder Joint Failures?

Imagine inspecting an ECU connector in a vehicle; X-ray imaging is your best tool for early detection. It reveals voids, cracks, or corrosion inside solder joints before they cause failures. You should also perform shear and pull tests for mechanical integrity and use thermal cycling to simulate real-world stresses. Combining non-destructive methods like X-ray with mechanical testing provides a thorough early-warning system for solder joint issues.

Conclusion

Remember, a solder joint is like the heartbeat of your car’s electronics—vibrating, flexing, and enduring harsh conditions. When it fails, it’s like a silent leak in an engine’s breath, risking your vehicle’s reliability. By understanding the common pitfalls and applying best practices, you can maintain that heartbeat strong. Regular checks and timely repairs guarantee your automotive connections stay resilient, so your car continues to run smoothly through every bumpy road and steady highway.