To fix electrical gremlins on aluminum-body trucks, start by inspecting and cleaning all grounding points, removing dirt, rust, or oxidation with a wire brush or cleaner. *Make certain* all ground connections are tight, corrosion-free, and secured to solid aluminum surfaces. Use anti-corrosion compounds and hardware designed for aluminum to prevent future issues. Regular checks help keep your electrical system reliable—continue exploring to get detailed steps on maintaining perfect ground connections.

Key Takeaways

- Inspect and clean grounding points regularly, removing dirt, rust, and oxidation with a wire brush or aluminum cleaner.

- Ensure grounding connections are solid, tight, and use hardware designed for aluminum to prevent corrosion.

- Apply dielectric grease or anti-corrosion compounds at grounding sites to protect against oxidation and moisture.

- Test grounding continuity with a multimeter; strive for low resistance to confirm reliable connections.

- Replace or relocate corroded or loose grounds to more accessible, corrosion-resistant locations for improved electrical stability.

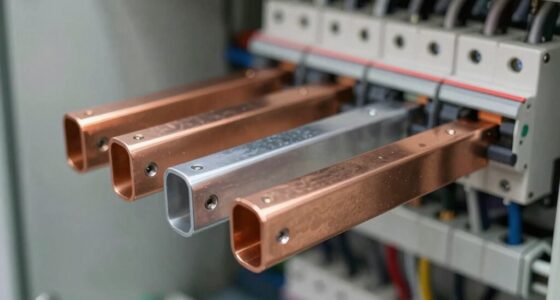

Aluminum-body trucks are gaining popularity because they offer a lighter weight alternative to traditional steel models, which can improve fuel efficiency and payload capacity. However, working with aluminum presents unique electrical challenges, especially when it comes to fixing those weird electrical gremlins that seem to pop up unexpectedly. One common culprit behind these issues is poor grounding. Proper grounding techniques are essential to guarantee your truck’s electrical system functions reliably. Aluminum doesn’t corrode the same way steel does, but it’s still susceptible to oxidation that can compromise connections. To keep your electrical system running smoothly, you need to pay close attention to grounding techniques. Use dedicated, clean, and secure grounding points, guaranteeing they’re free of dirt, rust, or oxidation. Applying dielectric grease or anti-corrosion compounds can help prevent corrosion at these points, maintaining a solid electrical connection over time.

Ensure solid aluminum grounding with clean, secure connections and anti-corrosion compounds for reliable electrical performance.

Corrosion prevention plays a critical role in maintaining the integrity of your truck’s electrical system. Aluminum components are more prone to galvanic corrosion when they come into contact with dissimilar metals or moisture. That’s why it’s imperative to inspect grounding points regularly and clean them thoroughly. When you notice corrosion or oxidation, remove it with a wire brush or a specialized cleaner designed for aluminum. After cleaning, reapply a protective coating or anti-corrosion spray to inhibit future oxidation. This step helps guarantee your grounds stay secure, preventing intermittent electrical issues that can be tricky to diagnose. Additionally, understanding the electrical properties of aluminum can help inform better maintenance practices and prevent future gremlins.

Another key aspect of fixing electrical gremlins involves checking your grounding connections for tightness and continuity. Loose or corroded grounds can cause a host of problems, from flickering lights to complete system failures. Use a multimeter to test continuity across your grounding points; if the readings aren’t zero or near zero ohms, it’s time to tighten or replace the connections. Also, consider relocating grounds to more accessible, corrosion-resistant points if you notice persistent issues. Keep in mind that aluminum’s conductive properties require more diligent maintenance compared to steel, so routine inspections should be part of your regular maintenance schedule.

In addition to grounding techniques and corrosion prevention, always use the right hardware designed for aluminum. This includes using fasteners that won’t cause galvanic corrosion or seize over time. Properly torqued bolts, combined with anti-seize compounds, can make a big difference in keeping your electrical system solid and reliable. By paying attention to these details and routinely inspecting your grounds, you’ll minimize electrical gremlins and extend the lifespan of your aluminum-body truck’s electrical system. Proper grounding and corrosion prevention are the foundation of fixing those mysterious electrical issues, guaranteeing your truck runs smoothly and reliably every time.

Frequently Asked Questions

Can Grounding Issues Affect Fuel Efficiency?

Grounding issues can definitely affect your fuel efficiency. When grounding corrosion occurs or grounding maintenance is neglected, electrical systems may struggle to operate properly, causing the engine to work harder. This extra effort consumes more fuel. Regularly inspecting and fixing grounding corrosion, along with proper grounding maintenance, guarantees your truck’s electrical system runs smoothly. This helps optimize fuel use and keeps your vehicle running efficiently.

Are Aluminum-Body Trucks More Prone to Electrical Problems?

Did you know that aluminum-body trucks can be 25% more prone to electrical issues? Yes, they are more susceptible to aluminum corrosion, which disrupts grounding connections. Regular grounding maintenance is essential to prevent this, as corrosion can cause weird electrical gremlins. You should inspect grounding points frequently, clean corrosion, and ensure proper grounding to keep your truck’s electrical system running smoothly and avoid costly repairs.

How Often Should Grounding Points Be Inspected?

You should inspect grounding points during regular grounding maintenance, ideally every 3 to 6 months. Frequent inspection guarantees connections remain clean and secure, preventing electrical gremlins. Pay close attention to corrosion or loose fittings, especially in aluminum-body trucks where grounding issues can cause problems. Keeping a consistent inspection schedule helps catch issues early, maintaining reliable electrical performance and reducing downtime caused by grounding-related gremlins.

Do Grounding Problems Impact Vehicle Safety?

Grounding problems can seriously impact vehicle safety by causing corrosion and electrical interference. When grounding corrosion develops, it weakens connections, risking electrical failures or malfunctions. Electrical interference from poor grounds can disrupt vital systems like brakes or steering, jeopardizing safety. So, if you neglect grounding issues, you risk risking your ride’s reliability and your safety, making regular inspections and maintenance a must for keeping everything connected, current, and secure.

What Tools Are Best for Diagnosing Grounding Issues?

You should use circuit testers and multimeter probes to diagnose grounding issues effectively. Circuit testers quickly identify if a circuit is live, while multimeter probes measure voltage, resistance, and continuity. By connecting these tools to suspect grounds, you can pinpoint poor connections or corrosion. Always verify your multimeter is set to the correct setting, and test thoroughly to avoid missing hidden faults in your vehicle’s grounding system.

Conclusion

Dealing with electrical gremlins in aluminum-body trucks can be tricky, but understanding grounds is key. Did you know that improper grounding can cause up to 80% of electrical issues? By ensuring solid, corrosion-free connections, you prevent mysterious malfunctions and keep your truck running smoothly. Remember, a simple check can save hours of troubleshooting. Fixing grounding problems not only restores reliability but also extends your truck’s lifespan, keeping you on the road without surprises.